Maintenance

Page 9

EPA assembly line for DaeP

Assembly Station

VPP 21

Station x

Station 2

Station 3

Station 4

Station 5

Station 6

Station 7

Station 8

Station 9

Station 10

Station 11

Station 12

Station 13

Station 14

Station 15

Station 16

Station 17

Station 18

Station 19

Station 20

Station 21

Station 22

Station 23

Station 24

Station 25

Station 26

Station 27

Station 28

Station 29

Station 30

Station 31

Station 32

Station 33

Station 34

Station 35

Station 36

Station 37

Station 38

Station 39

Station 40

Station 50

Station 60

Station 70

Station 80

Station 90

Station 100

Station 110

Station 120

Station 130

Station 140

Station 150

Station 160

Station 170

Station 180

Station 190

Station 200

Station 210

Station 220

Station 230

Station 240

Station 250

Station 260

Station 270

M.3000314.190_0843.195.960 /

V0.0_0613_EN_PA--ATMO2

Robert Bosch GmbH

Trouble Shooting

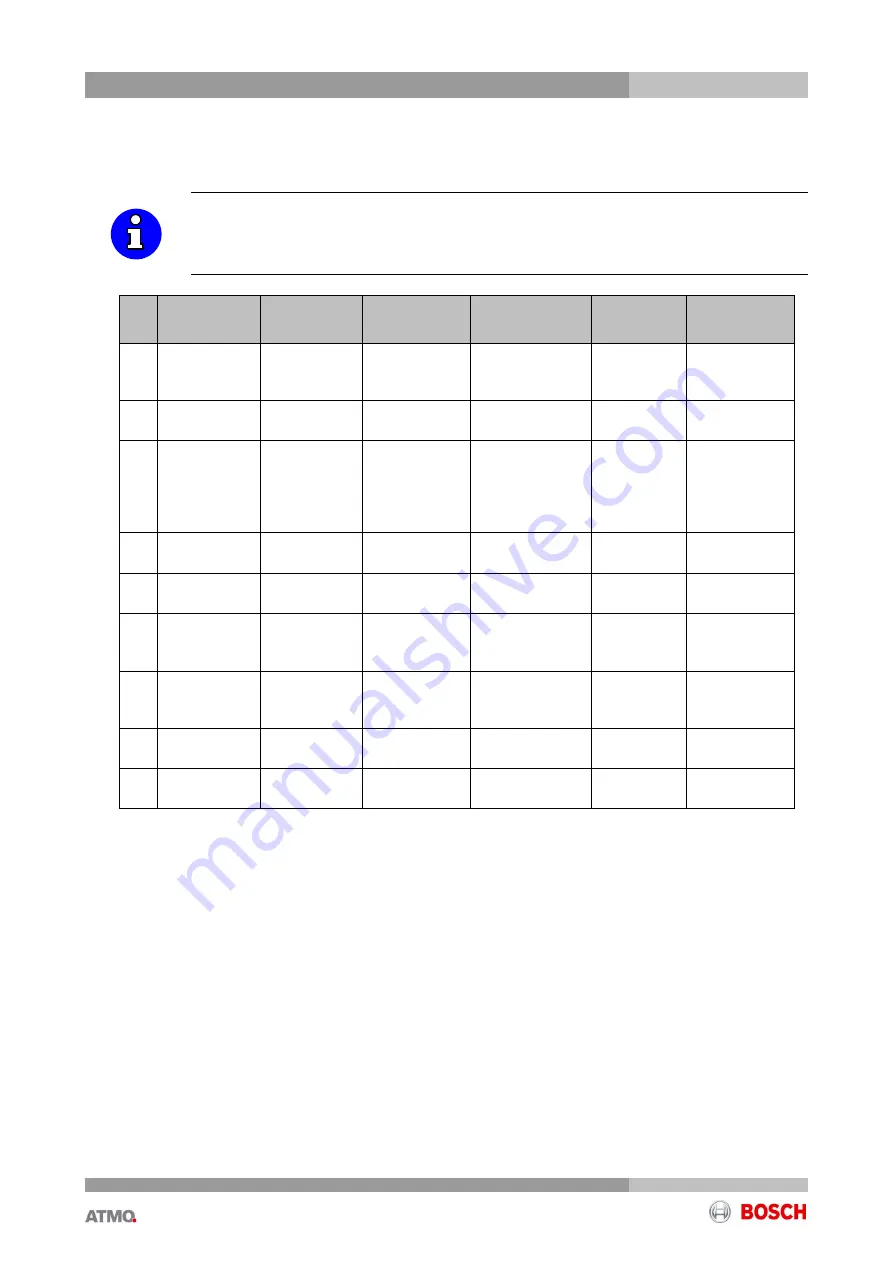

Periodic Inspection And Maintenance Chart

Sl.

no.

Inspection

area

Inspection

Unit

Inspection

method

Judgement

Standard

Action

Inspection

frequency

1

Main air

pressure

gauge

Pressure

Visual

Pressure --6 bar

Adjust

Daily

2

Air pressure

gauge

Pressure

Visual

Pressure --5 bar

Adjust

Daily

3

Air Filter

Soiling

Visual

Check for soil-

ing; Cleaning if

necessary, see

manual of

Bosch

Cleaning

Monthly

4

Machine

Area

Dirt

Visual

Free from

Dirt

Cleaning

Daily

5

All piping’s

Leaks

Visual

Feeling

Free from

Leak

Retighten

Weekly

6

Sealing pads

Cracks,

Damages

Visual

Free from

Cracks,

damages

Replace

Weekly

7

Pneumatic

cylinder

Operation &

leaks

Visual

Feeling

Smooth,

Free from

Leaks

Repair,

Replace

Weekly

8

All units

Tightened

condition

Spanners

Wrenches

Should be

Tight

Retighten

Check

Periodically

9

Electrical

terminals

Tightened

condition

Screw

Drivers

Free from

Looseness

Fully

Tighten

Monthly