Rev. 1.00

- 88 -

SRP-275II

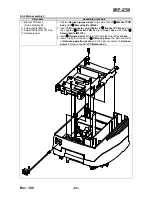

6. Adjustments and Maintenance

6-1 Adjustment

When assembling this printer, be sure to refer to the required adjustment procedure. To ensure normal

operation of the printer after disassembly or replacement of a Component for maintenance or repair. Be sure

to perform along to the required method.

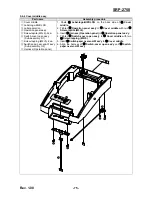

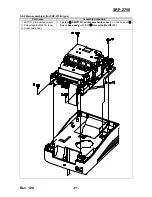

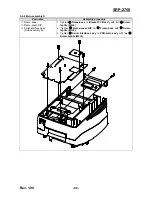

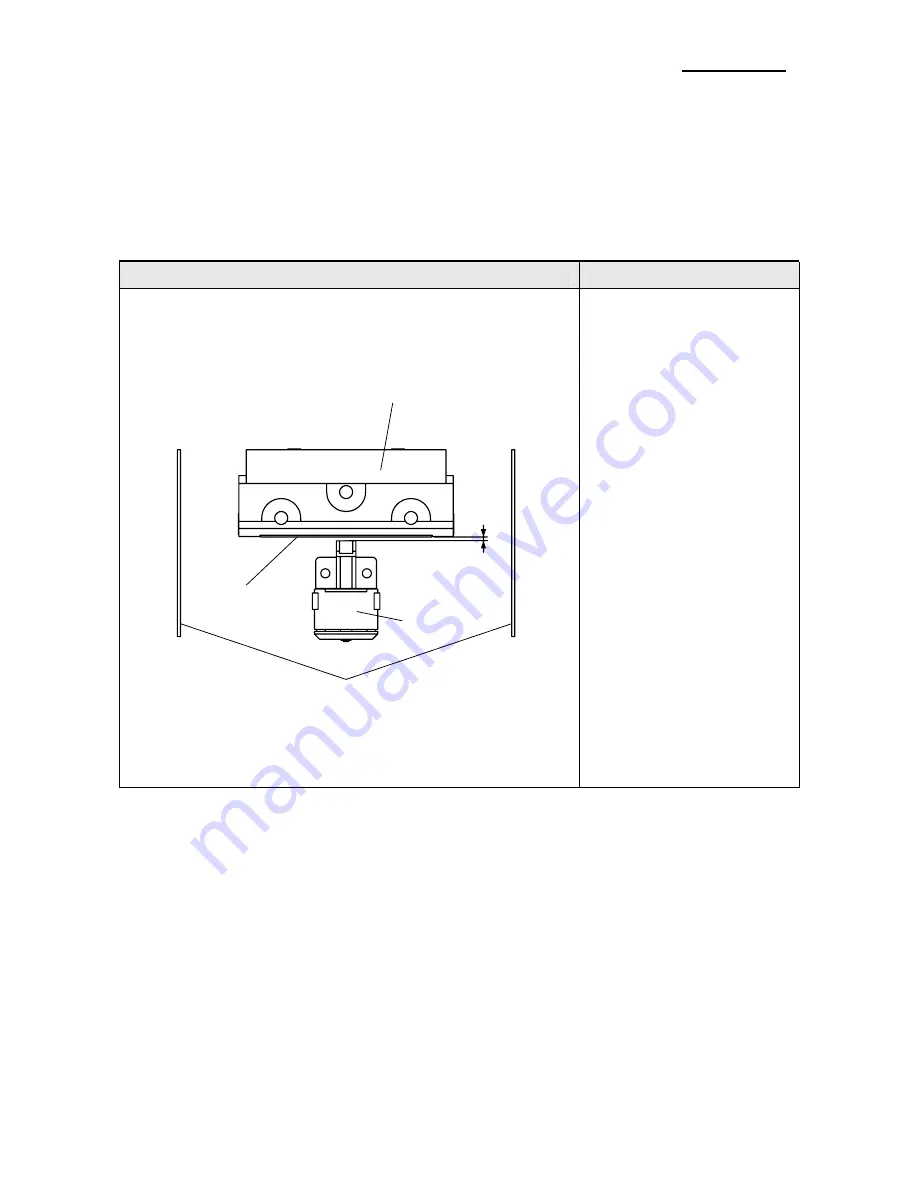

6-1-1 Adjustment of Head gap

Adjustment step and description points

In Adjustment

1) Move the

Printer-head

to L side.

2) Insert the thickness gauge between

Printer-head

and platen, then

rotate the

AD-lever L

and adjust the gap.

Gap

0.

4

0~

0.5

0

Printer-head

Frame-main

Platen

Holder platen

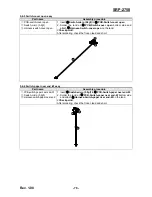

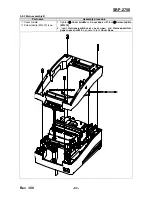

3) Move the

Printer-head

then check if the proper gap from R side

center has been achieved.

4) If head gap is not proper, adjust head gap by rotating

AD-lever R

.

Appropriate gap: 0.40~0.50mm

In order to make the gap narrow

(wide), turn

AD-lever

to mark

‘-(+)’

If gap is not correct, repeat once

more.

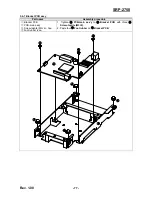

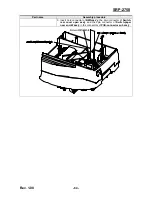

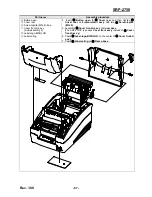

6-1-2 Replacement of Printer-head

Follow below steps for replacing

Printer-head

.

1) Loosen the

Frame-ribbon.

2) Disassemble the

Printer-head

from the

Carriage head ass’y

and take out the

FPC-head

from the

connector of PCB ass’y.

3) Replace the

Printer-head

and assemble, according to the order of

Sub-assembly E

.

4) After assembling, adjust the gap as above “Adjustment” indicates.

5) Assemble the

Frame-ribbon

.