20

8. Regular Inspection

Regular inspection are essential inspection procedures to secure safety (preventing vehicle falling

accidents and personal accidents) and to ensure the lift can be used for a long time, which are

performed along with the pre-operation check.

Be sure to perform the regular inspection at least once each month, in addition to the pre-operation

check that is performed every day, in order to ensure that the lift is used safely. In the event when even

slightly abnormal condition arises during routine use of the lift, immediately suspend the use of the lift

and make sure it is repaired properly and verify safety before using the lift.

Requesting the lift supplier where the lift was purchased for repairs on abnormality.

Inspected location

Inspection item

Synopsis of inspection

Referenced

section

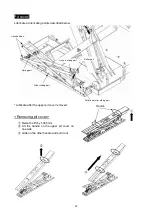

Lubricating location

Grease fittings

Lubricate each lubricating location

8-1

Inside pit

Drainage and foreign

matter inside the pit.

Raise the lift unit and verify to ensure the pit

is properly drained inside and there are no

foreign articles.

8-2

Lowering stop hook

Operating conditions of

lowering stop hook.

The lift must ascend while making clicking

sounds when raised.

8-3

Air circuit

Couplings and air tubes.

Verify to ensure there are no cracks or air

leaks.

Control panel

Electrical components

(magnet switch, relay,

etc.).

Verify to ensure they are operating normally,

that there are no damages or loose terminal

connections.

Bolts and nuts

Loosening.

Verify to ensure there is no loosening and

tighten as needed.

Lift unit

Rust conditions.

Verify to ensure there is no rust.

Arms

Operation of arm stop.

Thickness of arms.

Verify to ensure that arm stop operate when

the sliding arm is fully extended and that the

thickness of the arms is within standard

range.

Adjustable

supporters

Operation of stoppers.

Rattling.

Verify to ensure that stoppers are reliably

operating when the pads are rotated and

extended to the highest position and that the

rattling range is within 2 mm when moved up

and down while holding the supporter.

Couplers, upper

(Refer to “Lubricating

Locations Diagram” on

page 21)

Loosening of couplers,

upper.

Verify to ensure there is no loosening and tighten

as needed.

* If the part is loose, either replace the part or

tighten with screw locking glue and the like.

Have a qualified service personnel perform a periodical inspection once a year, in addition to

the regular inspection described above.

Request the lift suppliers where the lift was purchased for periodical inspection performed.

Notes for Using Safely