14

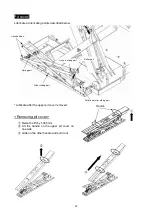

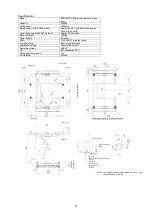

6-2. Inspecting Filter Regulator

The regulator features the function to reduce pressure of air supplied to the filter regulator (0.7 to 1.0

MPa) to the appropriate level of 0.7 MPa and to drain water in the air. Air pressure gauge shows the air

pressure after depressurization.

<Depressurizing method>

①

Verify that the pressure of air supplied to the filter

regulator is at least 0.7 MPa.

②

Loosen the screw on top of the filter regulator.

③

Look at the air pressure gauge while turning the

pressure adjustment knob to set the pressure to 0.7

MPa.

④

Tighten the screw on top of the filter regulator.

<Drain method>

①

Push up the draining valve.

Water sprays out with air.

* The appropriate value of the pressure of air (primary side pressure) supplied to the filter

regulator is between 0.7 and 1.0 MPa. The filter regulator may be damaged if the pressure is

greater than 1.0 MPa.

* Always make sure that the air pressure gauge is pointing 0.7 MPa before operating lift. The

lift may malfunction if the pressure is under 0.7 MPa. Furthermore, the Selex valve may be

damaged if the pressure is over 0.7 MPa. Always set the pressure to 0.7 MPa.

Drain water must be drained from the filter regulator every day.

Accumulation of water can cause malfunction.

Depres

surize

Pressurize

Screw

Pressure

adjustment knob

Air pressure

gauge

Caution

Caution

Drain valve