INSTALLATION MANUAL

ENGLISH

2) GENERAL OUTLINE

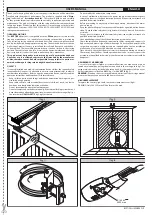

The BOTTICELLI system is suitable for motorising sectional doors (fig. 3), protrud-

ing fully retracting spring-operated overhead doors (fig. 2) and counterweight

overhead doors provided with an appropriate towing arm (fig. 4). The overhead

door must not be higher than 3 metres. Its easy installation allows fast fitting

without needing the door to be modified. The irreversible gearmotor keeps the

door locked in the closing position.

3) TECHNICAL SPECIFICATIONS

3.1) Actuator

Power supply:....................................................230V

~

±10%, 50/60Hz single-phase (*)

Motor voltage:.................................................................................................................24V

Max. power absorbed from mains:..............................................................................180W

Lubrication:.................................................................................................permanent grease

Towing and pushing force:..............................................................................................600N

Working stroke:....................................TRACK L.=2900 working stroke=2400 mm(**)

..................................................................TRACK L.=3500 working stroke=3000 mm(***)

Average speed:..............................................................................................................5 m/min

Impact reaction:..........................................integrated torque limiter on control panel

Manoeuvres in 24 hours:........................................................................................................20

Limit switch:..................................................................................Electronic with ENCODER

Courtesy light:..............................................................................24V

~

25W max, E14 bulb

Working temperature:.......................................................................................-15°C / +60°C

Degree of protection:..........................................................................................................IPX0

Motor head weight:...............................................................................................................5kg

Noise level:.....................................................................................................................<70dB(A)

Dimensions:.....................................................................................................................see fig.1

(*) Available in all mains voltages.

(**)By turning the motor head by 90° (Fig.11) the useful stroke will be 2580 mm.

(***)By turning the motor head by 90° (Fig.11) the useful stroke will be 3180 mm.

4) ACTUATOR INSTALLATION

4.1) Preliminary checks

• Check that the door is balanced.

• Check that the door slides smoothly along its entire travel.

• If the door has not been newly installed, check the wear condition of all its

components.

• Repair or replace faulty or worn parts.

• The automation reliability and safety are directly influenced by the state of

the door structure.

• Before fitting the motor, remove any superfluous ropes or chains and disable

any unnecessary appliances.

4.2) FITTING

After unpacking, dispose of the parts which make up the package properly, by

separating the different type of materials (cardboard, polystyrene, PVC,

etc.) according to the national rules in force.

1) Remove the existing locking bolt from the cremone bolt of the door.

2) Fit the metal wall bracket to the track-holder bracket using the screws sup-

plied as standard (Fig.12 Ref.E). The screws must not be tightened, so that

the bracket can be rotated.

3) In order for the track to be correctly fixed, mark the mid-point of the door,

position the BIN onto the ceiling and mark the holes (Fig.6).

Make sure that the distance between the track and the door panel is com-

prised between 108 and 166 mm (see Fig.14). If this is not the case, use the

brackets provided (Fig.10). If the distance is smaller, the towing plate must

be shortened.

The table in Fig.14A gives the various combinations for fas-

tening the bracket to the overhead door.

4) Drill the ceiling using a D.10 bit, with reference to the markings made previ-

ously, and insert the plugs.

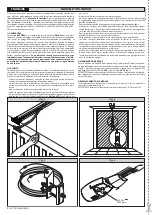

5) With the help of an adequate support, lift the entire motor, screw the screws

onto the track-holding bracket without fixing them to the door frame

(Fig.9A) or, if the height allows it, fit the bracket to the masonry lintel by

means of plugs (Fig.9B).

6) Rest the motor onto the floor (taking care not to damage it) and fix the

articulated bracket to the door frame or to the ceiling (Fig.9A, Fig.9B).

7) Lift the motor-driven head until everything rests against the ceiling and in-

sert the fixing screws which lock the track.

8) In the case where the motor is not directly fixed to the ceiling, fit the brack-

ets as shown in Fig.10 Ref.C, after marking and drilling the holes with refer-

ence to the brackets.

9) In the case where the track is made in two halves, see Fig.13; for the differ-

ent types of fixing methods, see the previous figures.

10) Release the carriage and fix the anchoring brackets to the door panel

(Fig.14). The distance allowed between track and sectional door is 108 to

166 mm. In case of greater distance, it is necessary to use the brackets and

lower the motor; in case of shorter distance, it is necessary to shorten the

towing plate.

11) Check that the carriage and anchoring bracket screws provide for correct

play of the towing bar.

12) Stick the adhesive labels supplied next to the dangerous points (Fig. 5).

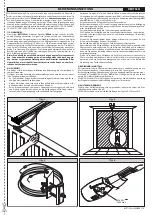

5) CHAIN TIGHTENER ADJUSTMENT (BOTTICELLI)

The operator supplied is already calibrated and inspected. Should the chain ten-

sion need to be adjusted, proceed as shown in fig. 15.

WARNING: the anti-tear rubber element must never be completely com-

pressed. Scrupulously check that the rubber does not become totally com-

pressed during operation.

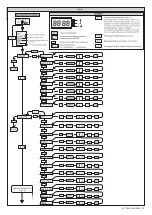

6) ELECTRICAL INSTALLATION SET-UP (Fig.16)

M) Actuator

Ft) Transmitter photocell

Fr) Receiver photocells

T) 1-2-4 channel transmitter.

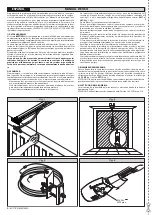

Arrange for the connections of accessories and safety and control devices to

reach the motor unit, keeping the mains voltage connections clearly separate

from the extra low safety voltage connections (24V) by means of the appropriate

cable holder (fig. 8 ref. 5P1).

Proceed to connection following the indications given in the wiring diagram.

The cables for connecting the accessories must be protected by a raceway (fig. 8 ref. 5C1).

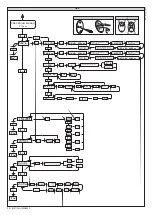

7) VENERE D Control panel (Fig.17)

Supply to accessories: ...........................................................................24V~ (180mA max)

........................................................................................24V~ Vsafe VENERE D (180mA max)

Torque limiter setting:..................................................................on closing and opening

Automatic closing time:..................................................................................from 1 to 180s

Blinker connection:.........................................................................................24V~ max 25W

Service light switching-on time:........................................................................................90s

Incorporated rolling-code radio receiver:................................frequency 433.92 MHz

Coding:.................................................................................................rolling-code algorithm

No. combinations:.......................................................................................................4 milliard

Antenna impedance:.......................................................................................50Ohm (RG58)

Max no. radio controls to be memorised:........................................................................10

Fuses:........................................................................................................................see figure 17

7.1) Terminal board connections (Fig.17)

WARNINGS - For wiring and installation operations, refer to the current

standards and good technical principles.

The wires supplied with extra low safety voltage (24V) must be kept physically

separate from the low voltage wires, or else they must be provided with adequate

additional insulation of at least 1mm.

The wires must be clamped by an extra fastener near the terminals, for example

by bands.

TERMINAL DESCRIPTION

JP2

transformer wiring

JP10

motor wiring

1-2

Antenna input for integrated radio-receiver board

(1: BRAID. 2: SIGNAL)

3-4

START input (N.O.)

3-5

STOP input (N.C.) If not used, leave the jumper inserted.

3-6

PHOTOCELL input (N.C.) If not used, leave the jumper inserted.

3-7

FAULT input (N.O.)

Input for photocells provided with checking N.O. contact

8-9

24 V~ output for blinking light (25 W max)

10-11

24V~ 180mA max output – power supply for photocells or

other devices

12-13

24V~ Vsafe 180mA max output – power supply for checking

photocell transmitters.

16-17

PARTIAL OPENING input

8) PROGRAMMING

The control panel with built-in microprocessor comes with factory settings, which

are valid for standard installations. The preset parameters can only be edited

using the built-in programmer with display or universal handheld programmer.

If you are performing programming via a universal handheld programmer, care-

fully read the relevant instructions for use of the universal handheld programmer

before proceeding as follows. Connect the universal handheld programmer

to the control unit by means of the UNIFLAT accessory. Enter the “CONTROL

UNITS” menu, then the “PARAMETERS” submenu and use the up/down arrows

to run through the screens on the display, entering the numerical values of the

parameters listed below.

For information on operating logics, refer to the “LOGIC” submenu.

If you are performing programming with the aid of the built-in programmer, refer

to Fig. A and B and to the “setup” section.

The meaning of each parameter and the values each can be given are listed below.

8.1) Setup

Via the programmer with display, you can set all the VENERE D control panel’s

functions.

The programmer has three buttons for navigating between menus and setting

operating parameters:

+

menu scroll/increase value key

-

menu scroll/decrease value key

OK return key (confirm).

Pressing the + and - keys at the same time allows you to exit the menu you are

working inside and move to the next menu up. If the + and - keys are pressed

at the same time when on the main menus (parameters-logic-radio-language-

default-autoset- limit switch adjustment), you exit programming and the display

switches off (the END message appears).

Changes only become operative if the OK key is pressed after they are made. The

first time you press the OK key, you enter programming mode.

To start with, the display gives the following information:

- Software version of control unit

- Total number of operations carried out (the value is given in thousands, hence

the display will keep showing 0000 for the first thousand operations)

- Number of operations carried out since last service (the value is given in thou-

sands, hence the display will keep showing 0000 for the first thousand operations)

- Number of memorized remote controls.

Pressing the OK key during the initial presentation allows you to skip to the first

menu (parameters-logic-radio-language-default-autoset-limit switch adjustment).

The main menus are listed below along with the relevant submenus available

for each.

The default setting is the one inside square brackets [ 0 ]

The message that appears on the display is shown inside round brackets.

Refer to Figures A and B for the control unit setup procedure.

8.2) Parameters Menu (

PARAM

)

- Automatic Closing Time (

TCA

) [ 40s ]

Set the numerical value of the automatic opening time in the range 1 to 180

seconds.

16 -

BOTTICELLI VENERE D

D811493 00100_02

Содержание Botticelli VENERE D

Страница 14: ...o vk 14 BOTTICELLI VENERE D D811493 00100_02...

Страница 45: ...146 253 16 65 378 35 3380 2780 3760 3160 1 2 250 E14 24V 25W max BOTTICELLI VENERE D 45 D811493 00100_02...

Страница 51: ...BOTTICELLI VENERE D 51 D811493 00100_02...

Страница 52: ......