Содержание Williams WBC110

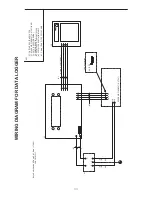

Страница 12: ...12 by OPERATING ENGINEERS MANUAL for WILLIAMS DATA LOGGER W D L with PRINTER MODULE...

Страница 19: ...19 by PARTS LISTS WIRING DIAGRAMS and CONTROLLER SET UP for REACH IN and ROLL IN BLAST CHILLERS...

Страница 20: ...20 PARTS LIST FOR A WBC35...

Страница 21: ...21 PARTS LIST FOR A WBC60...

Страница 22: ...22 PARTS LIST FOR A WBC75...

Страница 23: ...23 PARTS LIST FOR A WBC110...

Страница 24: ...24 PARTS LIST FOR A WMBC175 220 350 CONTROLLER WITH POD PRINTER...

Страница 25: ...25 PARTS LIST FOR A WMBC175 220 350 PANEL LAYOUT...

Страница 26: ...26 PARTS LIST FOR A WMBC175 220 350 EQUIPMENT...

Страница 27: ...27 PARTS LIST FOR A WMBC175 220 350 POD EQUIPMENT...

Страница 28: ...28 PARTS LIST FOR A WMBC175 220 350 PANEL LAYOUT...

Страница 29: ...29 PARTS LIST FOR A WMBC350 EQUIPMENT...

Страница 30: ...30 PARTS LIST FOR A WMBC480 660 PANEL LAYOUT...

Страница 31: ...31 PARTS LIST FOR A WMBC480 660 CONTROL PANEL WITH PRINTER POD...

Страница 32: ...32 PARTS LIST FOR A WMBC480 EQUIPMENT LAYOUT...

Страница 33: ...33 PARTS LIST FOR A WMBC660 EQUIPMENT LAYOUT...

Страница 34: ...34 PARTS LIST FOR A WMBC480 660 POD EQUIPMENT...

Страница 35: ...35 PARTS LIST FOR A WMBC480 660 PANEL LAYOUT...

Страница 49: ...49...

Страница 50: ...50...

Страница 51: ...51...