10

RULES OF THUMB

1. Pre-chill the cabinet for 30 minutes before you do first load

(this is to remove interior residual heat).

2. Doubling the food thickness triples the pull-down time.

3. Don’t stack food and / or containers on top or alongside or

each other.

4. Covering the food increases pull-down time by 10% -

30%.

5. Pull-down rate initially is about 2°F per minute and

approaching final temperature is about 2 minutes per

degree Fahrenheit.

6. Factors affecting blast chiller pull-down times:

-

Entering food temperature (the hotter the initial

temperature, the longer the pull-down time).

-

Final food temperature (the colder the final

temperature, the longer the pull-down time).

-

Food “thickness” (the greater the distance from

geometric “core” center of food to its surface pull-down

time).

-

Food density (the greater the density, the longer the

pull-down time).

-

Food thermal conductivity (the lower the conductivity,

the longer the pull-down time).

-

Food specific heats (the higher the specific heat, the

longer the pull-down time).

-

Container surface area (the smaller the surface area,

the longer the pull-down time).

-

Container material (metals are conductors and render

a shorter pull-down time than plastics which are

insulators).

-

Covering material (metal preferred instead of plastic

for reasons above).

-

Covering method-cover such as aluminium foil or a

“stretch wrap film” placed in direct contact with food

eliminates the “dead air space” between the cover and

the food. Since “dead air space” is an insulator,

elimination of reduction of it shortens pull-down time.

-

“Delta T” is temperature difference between the food

and the blast of air. The greater the “Delta T” the

quicker the pull-down time.

-

Air velocity (the greater the air velocity across the food,

the faster the pull-down time).

-

Amount (weight) of food put in as compared to rated

capacity machine. Exceeding the capacity increases

the pull-down time.

Содержание Williams WBC110

Страница 12: ...12 by OPERATING ENGINEERS MANUAL for WILLIAMS DATA LOGGER W D L with PRINTER MODULE...

Страница 19: ...19 by PARTS LISTS WIRING DIAGRAMS and CONTROLLER SET UP for REACH IN and ROLL IN BLAST CHILLERS...

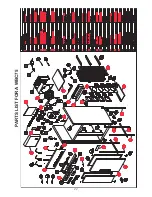

Страница 20: ...20 PARTS LIST FOR A WBC35...

Страница 21: ...21 PARTS LIST FOR A WBC60...

Страница 22: ...22 PARTS LIST FOR A WBC75...

Страница 23: ...23 PARTS LIST FOR A WBC110...

Страница 24: ...24 PARTS LIST FOR A WMBC175 220 350 CONTROLLER WITH POD PRINTER...

Страница 25: ...25 PARTS LIST FOR A WMBC175 220 350 PANEL LAYOUT...

Страница 26: ...26 PARTS LIST FOR A WMBC175 220 350 EQUIPMENT...

Страница 27: ...27 PARTS LIST FOR A WMBC175 220 350 POD EQUIPMENT...

Страница 28: ...28 PARTS LIST FOR A WMBC175 220 350 PANEL LAYOUT...

Страница 29: ...29 PARTS LIST FOR A WMBC350 EQUIPMENT...

Страница 30: ...30 PARTS LIST FOR A WMBC480 660 PANEL LAYOUT...

Страница 31: ...31 PARTS LIST FOR A WMBC480 660 CONTROL PANEL WITH PRINTER POD...

Страница 32: ...32 PARTS LIST FOR A WMBC480 EQUIPMENT LAYOUT...

Страница 33: ...33 PARTS LIST FOR A WMBC660 EQUIPMENT LAYOUT...

Страница 34: ...34 PARTS LIST FOR A WMBC480 660 POD EQUIPMENT...

Страница 35: ...35 PARTS LIST FOR A WMBC480 660 PANEL LAYOUT...

Страница 49: ...49...

Страница 50: ...50...

Страница 51: ...51...