page 99

page 99

page 99

page 99

page 99

475 A CRL

800-00167

CAT 330 CRAWLER LOWER MAINTENANCE

CAT 330 CRAWLER LOWER MAINTENANCE

CAT 330 CRAWLER LOWER MAINTENANCE

CAT 330 CRAWLER LOWER MAINTENANCE

CAT 330 CRAWLER LOWER MAINTENANCE

TRACK ADJUSTMENT PROCEDURE

TRACK ADJUSTMENT PROCEDURE

TRACK ADJUSTMENT PROCEDURE

TRACK ADJUSTMENT PROCEDURE

TRACK ADJUSTMENT PROCEDURE

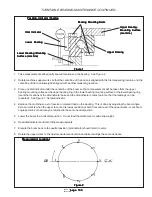

1. Drive the machine forward in the direction of the idlers.

2. Stop when one track pin is directly over the front carrier roller.

3. The correct adjustment is 25 to 40 mm (1.0 to 1.5 in.) of sag halfway between the front carrier roller and the

idler.

WARNING

WARNING

WARNING

WARNING

WARNING

To prevent possible personal injury, never visually inspect the relief valve

To prevent possible personal injury, never visually inspect the relief valve

To prevent possible personal injury, never visually inspect the relief valve

To prevent possible personal injury, never visually inspect the relief valve

To prevent possible personal injury, never visually inspect the relief valve

to see if grease is coming out. Always look at the track to see if it has

to see if grease is coming out. Always look at the track to see if it has

to see if grease is coming out. Always look at the track to see if it has

to see if grease is coming out. Always look at the track to see if it has

to see if grease is coming out. Always look at the track to see if it has

become loose or tight.

become loose or tight.

become loose or tight.

become loose or tight.

become loose or tight.

Open the relief valve one turn only.

CAUTION

CAUTION

CAUTION

CAUTION

CAUTION

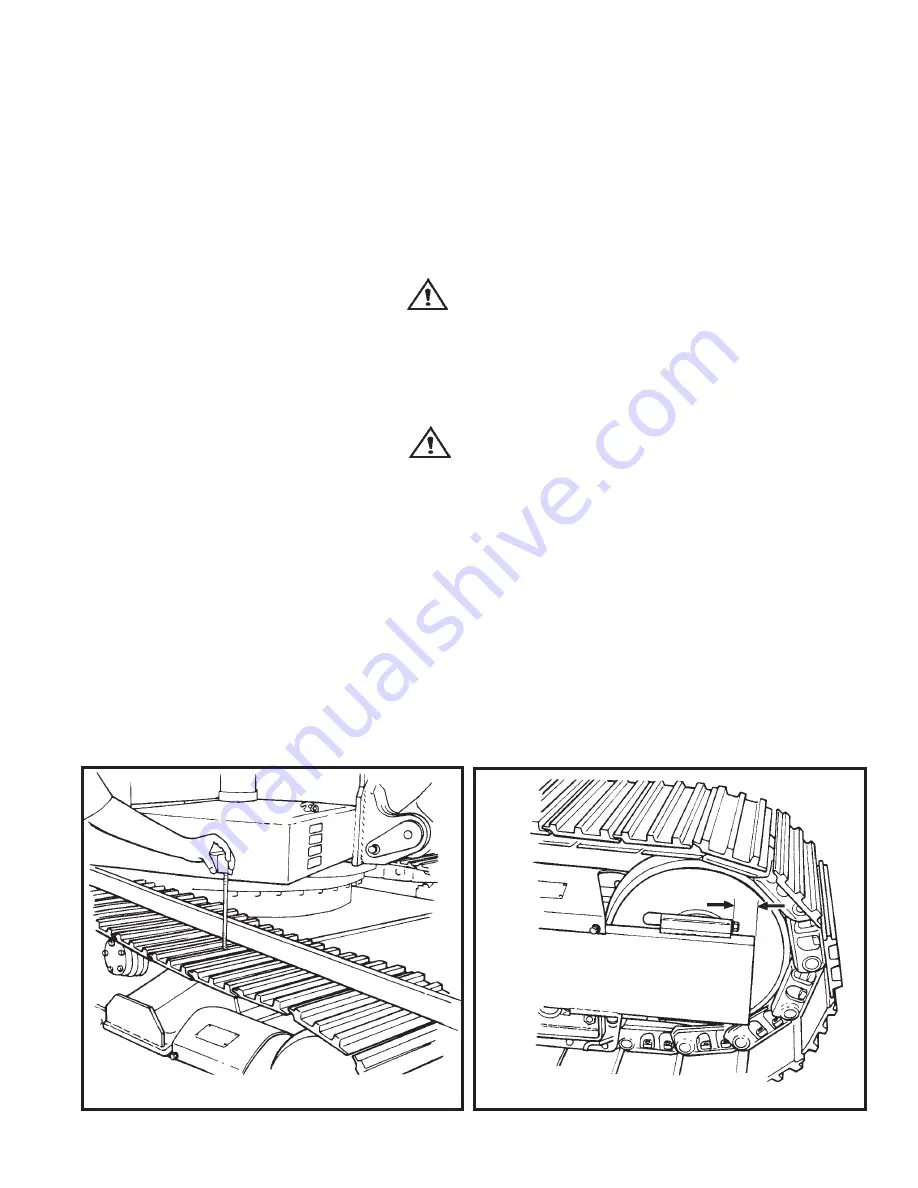

If the dimension between the end of the track roller frame and the flange

If the dimension between the end of the track roller frame and the flange

If the dimension between the end of the track roller frame and the flange

If the dimension between the end of the track roller frame and the flange

If the dimension between the end of the track roller frame and the flange

on the idler hub (as shown in Figure 2) is less than 25 mm (1 in.), do not adjust the

on the idler hub (as shown in Figure 2) is less than 25 mm (1 in.), do not adjust the

on the idler hub (as shown in Figure 2) is less than 25 mm (1 in.), do not adjust the

on the idler hub (as shown in Figure 2) is less than 25 mm (1 in.), do not adjust the

on the idler hub (as shown in Figure 2) is less than 25 mm (1 in.), do not adjust the

track.

track.

track.

track.

track.

4. Remove the plate covering the fill and relief valves on the track roller frame.

5. If the track is too loose, add grease in the fill valve until the track sag is correct.

6. If the track is too tight, turn the relief valve counterclockwise one turn and let grease come out until the

adjustment is correct.

NOTE

NOTE

NOTE

NOTE

NOTE: It will be necessary to move the machine back and forth to get the pressure equal.

7. Check the adjustment again.

8. If the adjustment is correct, tighten the relief valve and replace the cover plate.

Figure 1 - Measuring Track Looseness

Figure 1 - Measuring Track Looseness

Figure 1 - Measuring Track Looseness

Figure 1 - Measuring Track Looseness

Figure 1 - Measuring Track Looseness

Figure 2 - Measuring Track Looseness

Figure 2 - Measuring Track Looseness

Figure 2 - Measuring Track Looseness

Figure 2 - Measuring Track Looseness

Figure 2 - Measuring Track Looseness