page 21

page 21

page 21

page 21

page 21

475 A CRL

800-00167

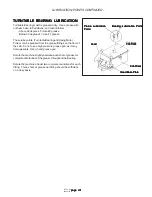

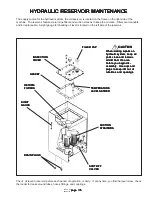

TURNTABLE BEARING LUBRICATION

TURNTABLE BEARING LUBRICATION

TURNTABLE BEARING LUBRICATION

TURNTABLE BEARING LUBRICATION

TURNTABLE BEARING LUBRICATION

Turntable Bearing must be greased daily. Use a grease with

a lithium base, EP additives, and rust inhibitors.

- Above 32 degrees F =Use #2 grease

- Below 32 degrees F = Use #1 grease

These lube points, (Turntable Bearing and Swing Motor

Pinion) can be greased from the grease fittings on the floor of

the cab. Do not use a high pressure grease gun, as it may

damage seals. Use a hand grease gun.

Rotate the machine slightly between each shot of grease for

complete distribution of the grease throughout the Bearing.

Rotate the machine at least two complete revolutions for each

fitting. Three shots of grease per fitting should be sufficient,

on a daily basis.

Bearing Lubrication Point

Bearing Lubrication Point

Bearing Lubrication Point

Bearing Lubrication Point

Bearing Lubrication Point

Pinion Lubrication

Pinion Lubrication

Pinion Lubrication

Pinion Lubrication

Pinion Lubrication

Point

Point

Point

Point

Point

Cab Deck

Cab Deck

Cab Deck

Cab Deck

Cab Deck

Head

Head

Head

Head

Head

Cab Riser

Cab Riser

Cab Riser

Cab Riser

Cab Riser

Head Base Plate

Head Base Plate

Head Base Plate

Head Base Plate

Head Base Plate

LUBRICATION POINTS CONTINUED...