page 24

page 24

page 24

page 24

page 24

475 A CRL

800-00167

LUBRICATE WITH ANTI-SEIZE COMPOUND PART NO. 514-00700

LUBRICATE WITH ANTI-SEIZE COMPOUND PART NO. 514-00700

LUBRICATE WITH ANTI-SEIZE COMPOUND PART NO. 514-00700

LUBRICATE WITH ANTI-SEIZE COMPOUND PART NO. 514-00700

LUBRICATE WITH ANTI-SEIZE COMPOUND PART NO. 514-00700

SPECIAL TORQUE SPECIFICATIONS

SPECIAL TORQUE SPECIFICATIONS

SPECIAL TORQUE SPECIFICATIONS

SPECIAL TORQUE SPECIFICATIONS

SPECIAL TORQUE SPECIFICATIONS

Swing Motor Mounting Bolts ........................................................................... 64 Ft. Lbs.

Swing Motor Gearbox Mounting Bolts ............................................................. 310 Ft. Lbs.

Turntable Bearing Bolts (Do not re-use old bolts/nuts.) .................................... 500 Ft. Lbs

Crawler Carbody Mounting Bolts (secure the carbody to the crawler tracks):

- Standard bolts ........................................................................................... 545 Ft. Lbs.

- Metric bolts ............................................................................................... 924 Ft. Lbs.

For Grapple Torques, see Grapple Service Manual.

WARNING

WARNING

WARNING

WARNING

WARNING

Loose or overtorqued bolts can cause death, severe injury, or property

Loose or overtorqued bolts can cause death, severe injury, or property

Loose or overtorqued bolts can cause death, severe injury, or property

Loose or overtorqued bolts can cause death, severe injury, or property

Loose or overtorqued bolts can cause death, severe injury, or property

damage. Maintain proper bolt torque. Visually check bolts daily. Check

damage. Maintain proper bolt torque. Visually check bolts daily. Check

damage. Maintain proper bolt torque. Visually check bolts daily. Check

damage. Maintain proper bolt torque. Visually check bolts daily. Check

damage. Maintain proper bolt torque. Visually check bolts daily. Check

torque every 50 hours.

torque every 50 hours.

torque every 50 hours.

torque every 50 hours.

torque every 50 hours.

WARNING

WARNING

WARNING

WARNING

WARNING

In critical applications (such as Turntable Bearing Bolts and any grade 8 or

In critical applications (such as Turntable Bearing Bolts and any grade 8 or

In critical applications (such as Turntable Bearing Bolts and any grade 8 or

In critical applications (such as Turntable Bearing Bolts and any grade 8 or

In critical applications (such as Turntable Bearing Bolts and any grade 8 or

grade 9 bolts), once the old bolts and nuts have been loosened, they must

grade 9 bolts), once the old bolts and nuts have been loosened, they must

grade 9 bolts), once the old bolts and nuts have been loosened, they must

grade 9 bolts), once the old bolts and nuts have been loosened, they must

grade 9 bolts), once the old bolts and nuts have been loosened, they must

be replaced rather than re-tightened and re-torqued. Original clamping

be replaced rather than re-tightened and re-torqued. Original clamping

be replaced rather than re-tightened and re-torqued. Original clamping

be replaced rather than re-tightened and re-torqued. Original clamping

be replaced rather than re-tightened and re-torqued. Original clamping

force cannot be achieved using the old bolts and nuts.

force cannot be achieved using the old bolts and nuts.

force cannot be achieved using the old bolts and nuts.

force cannot be achieved using the old bolts and nuts.

force cannot be achieved using the old bolts and nuts.

CRAWLER BOLT TORQUE

CRAWLER BOLT TORQUE

CRAWLER BOLT TORQUE

CRAWLER BOLT TORQUE

CRAWLER BOLT TORQUE

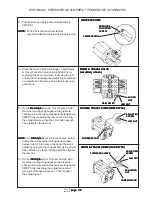

The Crawler Carbody Mounting Bolts, which mount the carbody to the crawler tracks, should be checked and retorqued,

if necessary, every 50 hours.

For standard bolts: torque to 545 Ft. Lbs of lubed torque.

For metric bolts: torque to 924 Ft. Lbs. of lubed torque.

See Figure 1.

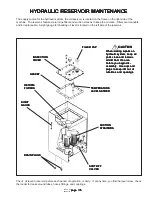

TRACKS

TRACKS

TRACKS

TRACKS

TRACKS

CARBODY

CARBODY

CARBODY

CARBODY

CARBODY

MOUNTING

MOUNTING

MOUNTING

MOUNTING

MOUNTING

BOLTS

BOLTS

BOLTS

BOLTS

BOLTS

CRAWLER CARBODY

CRAWLER CARBODY

CRAWLER CARBODY

CRAWLER CARBODY

CRAWLER CARBODY

CRAWLER LOWER ASSEMBLY

CRAWLER LOWER ASSEMBLY

CRAWLER LOWER ASSEMBLY

CRAWLER LOWER ASSEMBLY

CRAWLER LOWER ASSEMBLY

FIGURE 2

FIGURE 2

FIGURE 2

FIGURE 2

FIGURE 2