page 86

page 86

page 86

page 86

page 86

475 A CRL

800-00167

3. If any of these tests show zero voltage, repair or replace wiring.

4. Check voltage again until correct reading appears.

CHECKING ALTERNATOR OUTPUT

CHECKING ALTERNATOR OUTPUT

CHECKING ALTERNATOR OUTPUT

CHECKING ALTERNATOR OUTPUT

CHECKING ALTERNATOR OUTPUT

1. Disconnect negative battery cable.

2. Remove wire from "BAT" connector on alternator and fasten it to one connector of an ammeter. Fasten other

connector of ammeter to "BAT" connector of alternator.

3. Connect battery cable again.

4. Remove hot wire from electric solenoid on fuel injection pump and turn engine with starter for approximately

30 seconds to cause a partial discharge of battery.

5. Install hot wire on electrical solenoid and start engine and run at full engine RPM.

6. The ammeter reading must be within 10 percent of rated amperage marked on alternator case.

7. If reading is correct, alternator is good. If reading is more or less than 10 percent of rated amperage, check

regulator.

CHECKING THE REGULATOR

CHECKING THE REGULATOR

CHECKING THE REGULATOR

CHECKING THE REGULATOR

CHECKING THE REGULATOR

1. Use steps 1 through 5 of "Checking Alternator Output".

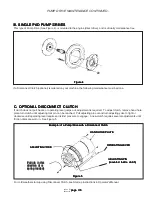

2. Put a small screwdriver in test hole. See Figure 3.

Alternator

Alternator

Alternator

Alternator

Alternator

No. 2 terminal

No. 2 terminal

No. 2 terminal

No. 2 terminal

No. 2 terminal

No. 1 terminal

No. 1 terminal

No. 1 terminal

No. 1 terminal

No. 1 terminal

"BAT" terminal

"BAT" terminal

"BAT" terminal

"BAT" terminal

"BAT" terminal

Test Hole

Test Hole

Test Hole

Test Hole

Test Hole

Figure 3

Figure 3

Figure 3

Figure 3

Figure 3

3. If the ammeter reading is not within 10 percent of rated amperage (marked on alternator case), regulator may

be damaged. Check diode trio, rectifier, stator, or rotor.

Damage to alternator can occur if:

-

battery connections are not connected properly.

-

wires from alternator are grounded.

-

engine is operated with battery cables disconnected.

-

cables are connected when using a fast charger or when welding on the loader. (Remove both cables

from the battery.)

-

extra battery cables (booster cables) are connected wrong.

ELECTRICAL SYSTEM MAINTENANCE CONTINUED...