12

There should also be an adequate increase in combustion air to meet the increase in fuel delivery.

Adjustment can be carried out at first regulation by operating the screws which vary the profile of the commend disk

of the combustion air regulator. Fuel and combustion air delivery both increase at the same time until they reach

maximum value (fuel pressure at the return pressure regulator is equal to about 18 ÷ 20 bar if the pressure at the

pump is at the value of 20 ÷ 22 bar).

Fuel and combustion air delivery remain at maximum value until the boiler temperature (pressure, if steam boiler),

approaches the value at which it has been set and causes the modulation control servomotor to reverse its previous

sense of movement. The return movement of the modulation servomotor causes a reduction in fuel delivery and a

relative reduction in combustion air.

The modulation system reaches a position of equilibrium which corresponds to a fuel delivery and a relative combustion

air delivery equal to the quantity of heat required by the boiler.

With the boiler operating, the probe in the boiler is aware of load variations in the boiler and automatically requests the

modulation. Servomotor to make an adjustment in the fuel delivery and in the relative combustion air. Should the

maximum temperature (pressure, if steam boiler) be reached even with fuel and combustion air delivery at a minimum,

the thermostat (pressure switch, if steam boiler) will intervene when the value at which it has been set is reached, and

bring the burner to a standstill. When the temperature (pressure, if steam boiler) drops below the intervention limit of

the “shut down” device, the burner will start up again as previously described.

It should be kept in mind that the field of variation in output obtainable with a good combustion is, as an indication,

from 1 to 1/3 of the maximum output given on the rating plate. When the flame does not appear within 3 seconds as

from the magneto connection, the control box sets in “lock out” position (total stop of the burner and relevant indication

of the signal lamp). To “release” the control box push the relative pushing button.

Note:

The air pressure switch must be set when the burners is started up and must be in function with the pressure

value verified during operation with the ignition flame.

N° 0002901000

N° 1 di 2

rev. 01/06/01

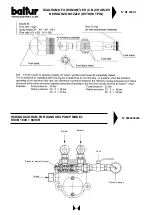

N.B. Ignition without gas pilot

burner only on TS 0 - 1 - 2

Connection to the feeding

circuit see BT 8910/2 and

BT 8911/1 for only one burner

Connection the feeding circuit

(see BT 8866/4 and BT 8868/2)

for more burner

Gas inlet

(Methane - L.P.G.) Max. pressure 300 mbar

for TS - GI 1000 / 500 mbar for PYR

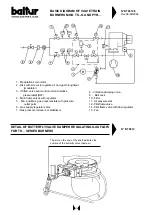

PRINCIPLE DIAGRAM FOR HEAVY OIL TS - PYR - GI 1000 MAIN

PUSHING SYSTEM (DEGASSING - FILTERING - PUSHING AND HEATING)

Piping to be made by the installer

Heating and thermic insulation

Содержание TS 0 GN

Страница 2: ......

Страница 47: ......

Страница 48: ......

Страница 49: ......

Страница 50: ......

Страница 51: ......

Страница 52: ......

Страница 53: ......

Страница 54: ......

Страница 55: ......

Страница 56: ......

Страница 57: ......

Страница 58: ......

Страница 59: ......

Страница 60: ......

Страница 61: ......

Страница 62: ......

Страница 63: ......

Страница 64: ......

Страница 65: ......

Страница 66: ......

Страница 67: ......

Страница 68: ......

Страница 69: ......

Страница 70: ......

Страница 71: ......

Страница 72: ......

Страница 73: ......

Страница 74: ......

Страница 75: ......

Страница 76: ......

Страница 77: ......

Страница 78: ......

Страница 79: ......

Страница 80: ......

Страница 81: ......

Страница 82: ......

Страница 83: ......

Страница 84: ......

Страница 85: ......

Страница 86: ......

Страница 87: ......

Страница 88: ......

Страница 89: ......

Страница 90: ......

Страница 91: ......

Страница 92: ......

Страница 93: ......

Страница 94: ......

Страница 95: ......