24

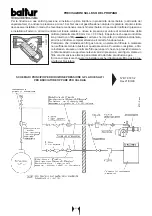

ELECTRICAL CONNECTIONS

The electric lines should be at an adequate distance from hot parts. It is advisable to make all connections with

flexible electric wire. Minimum section of conductors 1.5 mm

2

. (CEI 64/8 3.I.07).

DESCRIPTION OF OPERATIONS

Switch off the general switch, if the thermostats are off, and voltage goes to the command and control device which,

after a short interval (9 second), will start uf the burner according to the set program. The fan motor goes into

operation and makes the combustion chamber preventilation. At the end of the preventilation phase, the ignition

procedure will then start and, after 3 seconds, the safety valve and “first flame” (pilot light) valve will open up. A flame

will then apper, which will be detected by the flame control device, thus completing the ignition procedure.

The air shutter control servo will then be switched on, which will move to the second flame setting, as set by the

operator in each specific case, and at the same time an auxiliary contact on the servo will activate the second flame

valve. If the flame does not light, the burner will go into the “safety shutdown” state, 3 second after the opening of the

gas valves (pilot and safety). If a “safety shutdown” occurs, the gas valves will be closed immediately.

To go out of the shoutdown state, press the red button on the burner unit.

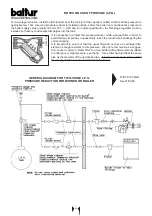

NATURAL GAS STARTING UP AND REGULATION

(for LPG operation see the relative chapter)

In order to proceed with starting up, it’s necessary, if the burner is three-phase, to check that the sense of rotation of

the motor is correct. If not already done so at the moment of connecting the burner to the gas pipeline, it’s indispensable

to carry a purge of the air contained in the pipeline.

As a precaution, special care should be taken and doors and windows should be opened. Open the pipe union on the

pipeline situated near the burner and then open a little the cut-off cock (or cocks).When the characteristic odour of

gas can be smelled, close the cut-off cock. Wait until the gas present in the room has dispersed, and then reconnect

the burner to the gas pipeline. Then proceed as follows:

1) Make sure that the discharge of combustion products can take place freely (chimney lock-gates should be open)

and that there is water in the boiler.

2) Open as much as considered necessary, the combustion air regulator, (see “servomotor for regulating air shutter

type LKS 120-02 (B5-5-51)”) and open by about one third the air passage between the head and the flame disk

(diffuser) (see “Regulation of the combustion Head”).

3) Operate the regulators incorporated in the gas valves in such a way as to obtain the gas delivery presumed

necessary.

4) Disconnect the 2nd flame thermostat and give current to the burner by opening the main switch.

The burners is then turned on and carries out the pre-ventilation phase. If the air pressure exceeds that value at

which the air pressure switch has been set, the ignition transformer will be connected and, subsequently, the

gas valves (safety and 1

st

flame) will be inserted.

The valves open completely and gas delivery is limited to the position at which the flow regulator incorporated in

the 1

st

flame (pilot) valve has been manually regulated. At first ignition, successive “shut downs” could occur, due

to the following reasons:

a - The gas pipeline has not been adequately purged of air and therefore the quantity of gas is not sufficient to

allow for a stable flame.

b - A “shut down” with flame presence could be caused by flame instability in the ionisation zone, due to and

incorrect air/gas ratio. This can be remedied by varying the quantity of air and/or gas delivered, in order to find

the correct ratio. It could also be caused by an incorrect distribution of air/gas in the combustion head. This can

be corrected by operating the regulation device of the combustion head by closing or opening more the air

passage between the head and the gas diffuser. See chapter “regulation of the combustion head”.

c - It could happen that the ionisation current is help up by the current discharged from the ignition transformer (the

two currents have to run the same course on the burner’s ”earth”) and so the burner goes to “shut down” due

to insufficient ionisation. This can be remedied by inverting the input (220V side) of the ignition transformer

(change the places of the two wire that take voltage to the transformer). A shut down with flame presence could

also be caused by the burner’s casing not being properly “grounded”.

We must point out that the minimum value of the ionisation current to ensure the working of the control box is

shown in the electrical diagram; normally the ionisation current is decidedly higher.

To check the ionisation current, connect a microammeter with an adequate scale “in series” to the ionisation

circuit. The cable of the ionisation electrode is equipped with a connector (see circuit diagram) to facilitate the

micro-ammeter connection. The high isolation wire that comes from the electrode must be inserted to the

negative (sign -) of the microammeter.

SPARKGAS 3,6 - 6 - 11 P

Содержание SPARKGAS 3,6

Страница 14: ...14...

Страница 15: ...15...

Страница 16: ...16...

Страница 17: ...17...

Страница 27: ...27...

Страница 28: ...28...

Страница 29: ...29...

Страница 30: ...30...

Страница 40: ...40...

Страница 41: ...41...

Страница 42: ...42...

Страница 43: ...43...

Страница 53: ...53...

Страница 54: ...54...

Страница 55: ...55...

Страница 56: ...56...

Страница 66: ...66...

Страница 67: ...67...

Страница 68: ...68...

Страница 69: ...69...