52 / 119

0006081062_200709

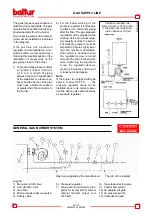

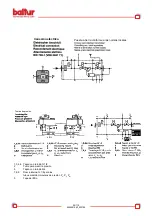

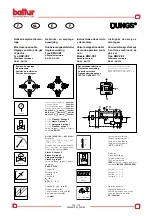

BGN 540 LX / LX-V ELECTRODES ADJUSTMENT DIAGRAM

N° 0002933850

Rev. 12/06/2002

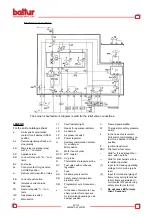

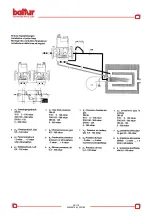

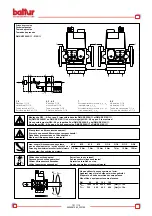

CONTROL BOX FOR LFL 1... SERIES 02 GAS BURNERS

Control box for burners of ave-

rage and high power, with forced

draught, intermittent service

(*), 1 or 2 stages, or modulating

types, with supervision of the

air pressure for controlling the

air damper.

This control box bears the EC

mark, in accordance with the Gas

and Electromagnetic Compatibi-

lity Directive.

* For reasons of safety, it is neces

-

sary to make at least one control

-

led stop every 24 hours!

As regards the standards

The following LFL1… features

exceed the standards, offering a

high level of additional safety:

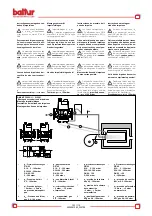

- The flame detector test and false

flame test start immediately after

the tolerated post-combustion

time. If the valves remain open,

or do not close completely after

adjustment stops, a lock-out stop

is triggered at the end of the to-

lerated post-combustion period.

The tests will end only at the end

of the pre-ventilation time of the

next start-up.

- The validity of working of the

flame control circuit is checked

each time the burner starts up.

- The fuel valve control contacts

are checked for wear during the

post-ventilation time.

- A built-in fuse in the appliance

protects the control contacts from

any overloads that may occur.

As regards the burner control

- The equipment allows operation

with or without post-ventilation.

- Controlled activation of the air

damper to ensure pre-ventilation

with nominal airflows. Positions

checked: CLOSED or MIN (posi

-

tion of ignition flame on start-up);

OPEN at the beginning and MIN

at the end of the pre-ventilation

time. If the servomotor does not

position the air damper at the

points described, the burner does

not start-up.

- Ionization current minimum value

= 6mA

- UV cell current minimum value =

70mA

- Phase and neutral must not be

inverted.

- Any place may be used for in

-

stallation and assembly (IP40

protection).

Содержание BGN 200 LX

Страница 27: ...54 119 0006081062_200709 Notes on the programmer Programmer sequence Output signals on terminal...

Страница 35: ...98 119 0006081062_200709...

Страница 36: ...99 119 0006081062_200709...

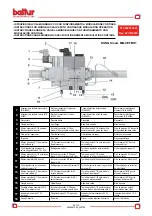

Страница 44: ...107 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Страница 45: ...108 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Страница 46: ...109 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Страница 47: ...110 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Страница 48: ...111 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Страница 49: ...112 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Страница 50: ...113 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Страница 51: ...114 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Страница 52: ...115 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Страница 53: ...116 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Страница 54: ...117 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Страница 55: ...118 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...

Страница 56: ...119 119 0006081062_200709 SCHEMA ELETTRICO WIRING DIAGRAM ELECTRIC DIAGRAM...