5

5

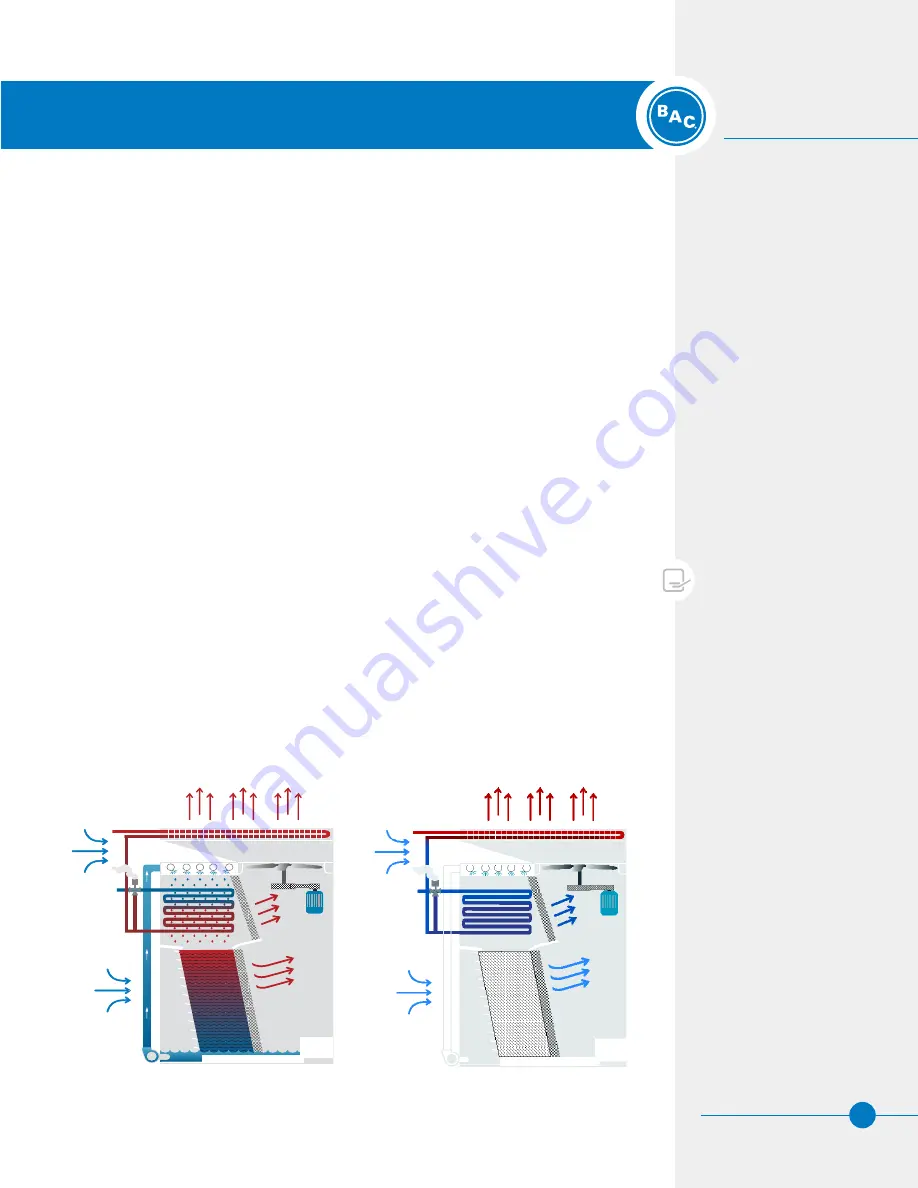

Operation

To optimize water and energy savings, the HXV Hybrid Cooler operates in two modes. In each

mode, capacity is controlled by fan motor modulation, and all of the process fluid flows

through the finned coil (dry coil) and then through the prime surface coil (wet coil).

Operating Modes

(Con’t next page)

•

Energy Saver Mode (Wet Mode)

: The spray water circulating pump distributes water

over the outside of the prime surface coil (wet coil). The spray water falls from the

prime surface coil over the fill surface, where the spray water temperature is further

reduced through evaporation. The cooled spray water collects in the cold water basin,

passes through the suction strainer and is pumped through the distribution system.

The fans draw air through the prime surface coil and through the fill surface (sensible

and latent heat transfer), which saturates the air before it enters the plenum and flows

into the fans. The saturated discharge air from the fans passes over the finned coil (dry

coil) to cool the process fluid (sensible heat transfer). This mode take full advantage of

evaporative cooling, and therefore reduces the fan energy necessary for cooling.

•

Water Saver Mode (Dry Mode):

The process fluid flows through the finned coil (dry coil)

and the prime surface coil. However, the spray water circulating pump is turned off,

which saves pump energy. There is only sensible heat transfer across both coils, as

the air passes over them. This mode is typically used during periods of lower ambient

temperatures or lower heat loads. During prolonged periods of dry mode operation,

draining the cold water basin is recommended, minimizing the need for freeze protection

and water treatment.

Unit Operation and

Storage

Operation

Figure 2a.

Energy Saver Mode

Figure 2b:

Water Saver Mode

Internal Access Ladder

and Platform

NOTE:

Schematic drawings are not

representations of actual units.

Refer to submittal for your specific

configuration.