Introduction

xix

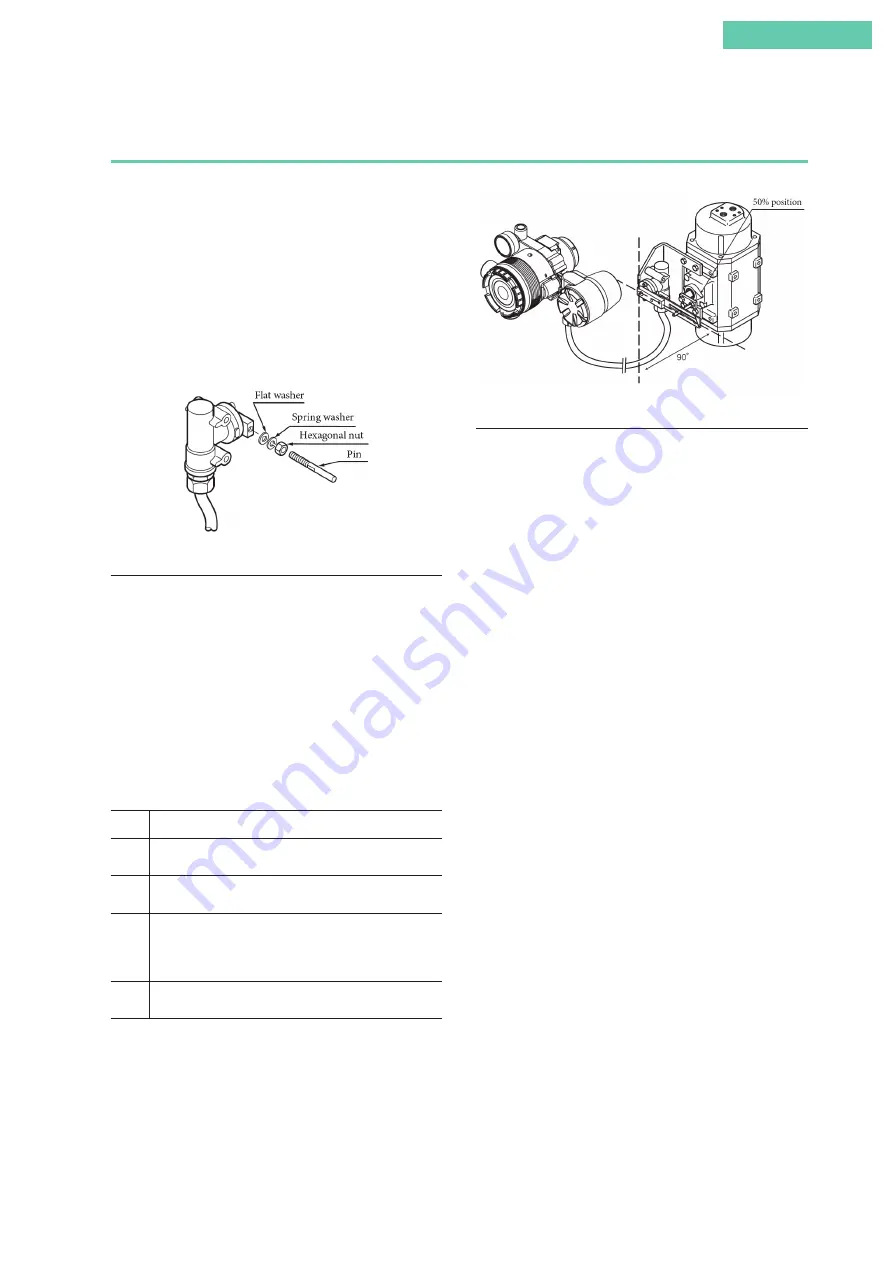

Combination of model AVP200/201/202 (remote type) and single-acting rotary cylinder

actuator

1. Attachment of feedback lever (pin)

In order to minimize the risk of damage to the feedback lever

while it is carried or transported, and to minimize the pack-

aging as well, the feedback lever is detached from the valve

travel detector when it is packed. As a result, the feedback

lever (pin) must be attached to the valve travel detector prior

to installation of the device.

Using the two accompanying hexagonal nuts, attach the feed-

back lever (pin) firmly to the valve travel detector as shown

in the diagram.

Attachment of feedback lever (pin)

2. Attachment and installation

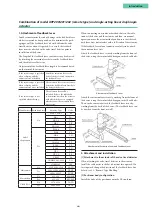

[1] Attachment to the actuator of the valve travel detector

When attaching the valve travel detector to the actuator,

install the cable outlet such that it does not face upward. If it

faces upward, change the direction of the feedback lever. For

details, see 2.3, “Remote Type Handling.”

[2] Positioner body configuration

Install the body of the positioner onto the 2B stanchion.

[3] Adjustment of attachment positions

Procedure for adjustment of attachment positions

Step

Procedure

1

Set the A/M switch to manual operation.

(See 5.2, “A/M Switch.”)

2

Supply air, and adjust the actuator air pressure such that the

position reaches the travel midpoint.

3

By adjusting the attachment position of the arm that

holds up the feedback pin, adjust the actuator such that

the feedback lever reaches a 90° angle to the valve travel

detector's central vertical axis.

4

Set the A/M switch to automatic operation.

(See 5.2, “A/M Switch.”)

Note: The accuracy specifications can be satisfied by making

the attachment angle 90° ± 2°.

Adjustment of Attachment Positions

3. Air piping and electric wiring connection

[1] Air piping connection

For details, see air piping connection in 2.2, “Installation

Method,” in this document.

[2] Electrical wiring connection (cables between valve

travel detector and positioner)

When shipped from the factory, the valve travel detector and

the positioner body are normally shipped separated at the

connector unit on the positioner body.

Referring to 2.3, “Remote Type Handling,” in this document,

connect the valve travel detector cable to the body of the

device using the remote cable. When laying cable, follow ap-

propriate electrical work guidelines.

Содержание AVP200

Страница 30: ......

Страница 66: ...2 28...

Страница 80: ...4 4 Menu Tree...

Страница 120: ...5 16...

Страница 128: ...6 8 For models those date of manufacture are before September 2017...

Страница 129: ...6 9 Chapter 6 Cautions regarding Explosion Proof Models For models those date of manufacture are before September 2017...

Страница 130: ...6 10 For models those date of manufacture are before September 2017...

Страница 131: ...6 11 Chapter 6 Cautions regarding Explosion Proof Models For models those date of manufacture are before September 2017...

Страница 132: ...6 12 For models those date of manufacture are before September 2017...

Страница 133: ...6 13 Chapter 6 Cautions regarding Explosion Proof Models For models those date of manufacture are after October 2017...

Страница 135: ...6 15 Chapter 6 Cautions regarding Explosion Proof Models For models those date of manufacture are after October 2017...

Страница 136: ...6 16 For models those date of manufacture are after October 2017...

Страница 138: ...6 18 For models those date of manufacture are after October 2017...

Страница 139: ...6 19 Chapter 6 Cautions regarding Explosion Proof Models For models those date of manufacture are after October 2017...

Страница 184: ...Appendix A Specifications A 25...

Страница 185: ......

Страница 188: ......

Страница 190: ......