8

6.3

Adjusting seal temperature/speed

Use the PROG-button to change the adjustments. The leds indicates which adjustment is selected. After 30

seconds from the last button pressure, the program returns automatically to the actual seal temperature.

To find the ideal sealing temperature and speed. Make a couple of trial seals with different adjustments. The

settings for a good seal are a combination between sealing temperature (TEMP) and on the other side the

operation speed (SPEED).

Adjust the next parameters:

−

The sealing temperature to 100°C.

−

The operation speed “speed” to 50.

Follow the next steps to adjust the seal temperature and the operation speed:

−

Press on PROG.

−

Led TEMP/SET illuminates and the display shows the actual adjusted temperature.

−

Press on UP/DOWN to raise or lower the adjusted temperature.

−

Press on PROG.

−

Led SPEED/SET illuminates and the display shows the actual adjusted operation speed.

−

Press on UP/DOWN to raise or lower the adjusted operation speed.

−

Press the PROG-button again to return to the actual temperature.

The led of the seal temperature TEMP/ACT flashes if the temperature deviation is more than 5 degrees from

the adjusted value.

Make a couple of bags. Re-adjust if the bags are not sealed properly.

−

The seals are not tight. The sealing temperature is too low and the operation speed too high.

−

The seals looks melted. The sealing temperature is too high and the operation speed too low.

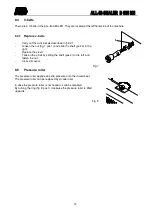

6.4

Cool run

Turn off the machine with the START/STOP-button. The machine will cool down to 80°C in the cool run

mode. After the cool run mode the machine automatically switches off to the standby mode. During the cool

run mode the motor and fan turn on and the heater turns off automatically. The cool run protects the PTFE-

belts against burning. That will increase the life cycle of the belts. Below 80°C the cool run turns off the

machine immediately to the standby mode.

The START/STOP led flashes during the cool run. The display shows intermittent “c-r” and the actual

temperature.

6.5

Standby

Turn the machine off with the cool run. After the cool run mode the machine automatically switches off to the

standby mode. The display shows “- - -“ and all functions are shut down. Press a button to turn the machine

on again. If the All-in is not to be used for a long period of time, use the main switch (POWER) to turn off the

machine. In this way the current is shut down.

Содержание D 555 NH

Страница 1: ...AUDION ELEKTRO ALL IN SEALER D 555 NH MANUAL D555 NH ENG Rev06...

Страница 20: ...Appendix A1 14 Electrical circuit...

Страница 21: ...Appendix A2 Electrical circuit...

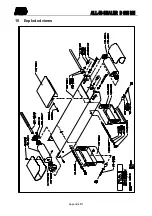

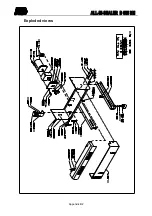

Страница 22: ...Appendix B1 15 Exploded views...

Страница 23: ...Appendix B2 Exploded views...

Страница 24: ...Appendix B3 Exploded views...

Страница 25: ...Appendix B4 Exploded views...

Страница 26: ...Appendix B5 Exploded views...