D 3.1 15

D_3

.1_0

1_G

B.

fm

1

5

-1

6

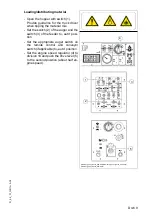

Adjustment of screed eccentric (

o

)

(104)

To pave thicker layers of material, if the

piston rods in the levelling cylinder are

operating close to their limit position and

if the desired paving thickness cannot be

reached, it is possible to alter the ap-

proach angle of the screen by adjusting

the eccentric.

- Pos I:

Paving thickness of up

to approx. 7cm

- Pos II:

Paving thickness of approx.

7 cm to approx. 14cm

- Pos III: Paving thickness above

approx. 14 cm

- The spindle (A) is not adjusted.

- Unfasten lock nuts (B) for eccentric adjustment.

- Swivel screed into desired position using lever (C) then engage the locking knob

once again.

A

If the levelling unit is connected to a height controller, this has the function of balanc-

ing out any rapid rise in the screed position: The levelling cylinders are extended until

the correct height is reached.

A

The change in approach angle can only take place slowly and uniformly on both sides

at once during paving operation, and involves the use of the eccentric adjustment.

Failing this, any rapid response in the screed could easily cause waves to appear on

the road surface.

The setting process should therefore take place before work starts!

Wetterhaus.eps

(

o

)

C

B

III

II

I

A

Содержание DYNAPAC Svedala Demag DF 115 C

Страница 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Страница 10: ......

Страница 18: ......

Страница 20: ......

Страница 44: ......

Страница 58: ......

Страница 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Страница 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Страница 66: ...D 1 4 8 D_1 4_01_GB fm 8 22 Element2_konv_Kette_635 bmp 27 19 18 17 28 29 B 16 25 26 22 21 20 23 24...

Страница 68: ...D 1 4 10 D_1 4_01_GB fm 10 22 Element2_konv_Kette_635 bmp 27 19 18 17 28 29 B 16 25 26 22 21 20 23 24...

Страница 70: ...D 1 4 12 D_1 4_01_GB fm 12 22 Element2_konv_Kette_635 bmp 27 19 18 17 28 29 B 16 25 26 22 21 20 23 24...

Страница 96: ......

Страница 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Страница 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Страница 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Страница 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Страница 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Страница 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Страница 134: ......

Страница 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Страница 147: ...E 01 13 E_01_GB fm 13 18 3 1 Mounting extension parts Sch_ver1 tif Sch_ver2 tif 16 5 9 10 8 7 6 14 15 12 11 12 5...

Страница 152: ......

Страница 154: ......

Страница 155: ...F_2 3_01_GB fm 1 2 F 2 3 1 F 2 3 Maintenance overview 1 Maintenance review 7 2 4 1 3 5 1 6 8 9 10...

Страница 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Страница 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Страница 168: ......

Страница 180: ......

Страница 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Страница 189: ...F 7 2 1 F_7 2_01_GB fm 1 4 F 7 2 Maintenance Running gear 1 Maintenance running gear 635_ISO_Dyn bmp LW_DEM_inter bmp 43...

Страница 193: ...F 8 1 1 F_8 1_01_GB fm 1 20 F 8 1 Maintenance Electronic System 1 Maintenance Electronic System...

Страница 220: ......

Страница 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Страница 226: ......