B 5

B

635_

D

E

M

.D 5

-24

01-

01.

07.

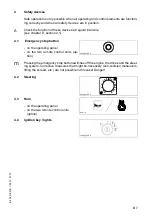

Automatic levelling/slope control system: The slope control system (option) al-

lows the regulation of the traction point either on the LH or RH sides, by maintaining

a difference defined against the opposite side.

To determine the actual value, the two traction arms are linked with a slope control

rod.

The slope control system always operates in conjunction with the screed height ad-

justment of the opposite side.

By adjusting the height of the traction point of the arm (traction roller), the paving

height of the material or the laying height of the screed can be controlled.

Actuation occurs electro-hydraulically on both sides and can be controlled manually

by means of toggle switches or automatically (by means of an electronic grade control

system).

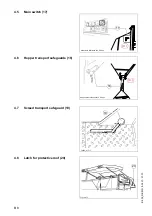

The screed lifting system: The screed can be lifted to transport height using the

screed lifting system. Lifting occurs electro-hydraulically on both sides by actuating

the hydraulic cylinders on the arms and is controlled by means of toggle switches on

the operating panel.

Automatic screed stop and screed charging/relieving device: The automatic

screed stop prevents the screed marks caused by a stopped screed. When the paver

is stopped (during a truck change), the screed remains in floating position and the re-

lieving pressure is turned on, therefore, the sinking of the screed can be avoided while

stopped.

The screed relieving device puts a higher load on the chassis, thus increasing the

traction.

Activating the screed charging device can improve the compacting result under cer-

tain conditions.

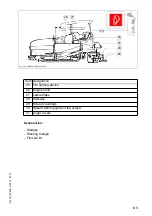

Exhaust of asphalt vapours (

o

): The asphalt vapours are extracted by a hydrauli-

cally driven exhaust head mounted in the material tunnel or over the auger. The va-

pours collected are discharged together with the exhaust fumes of the internal

combustion engine.

Central lubrication unit (

o

): The central lubrication pump fitted with a large lubricant

tank supplies grease to the various lubrication circuits through various flow dividers.

They supply lubricant to the service-sensitive points of lubrication (e.g. bearings) by

adjustable intervals.

Содержание DYNAPAC Svedala Demag DF 115 C

Страница 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Страница 10: ......

Страница 18: ......

Страница 20: ......

Страница 44: ......

Страница 58: ......

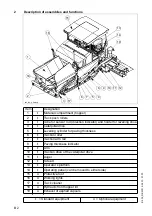

Страница 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Страница 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Страница 66: ...D 1 4 8 D_1 4_01_GB fm 8 22 Element2_konv_Kette_635 bmp 27 19 18 17 28 29 B 16 25 26 22 21 20 23 24...

Страница 68: ...D 1 4 10 D_1 4_01_GB fm 10 22 Element2_konv_Kette_635 bmp 27 19 18 17 28 29 B 16 25 26 22 21 20 23 24...

Страница 70: ...D 1 4 12 D_1 4_01_GB fm 12 22 Element2_konv_Kette_635 bmp 27 19 18 17 28 29 B 16 25 26 22 21 20 23 24...

Страница 96: ......

Страница 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Страница 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Страница 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Страница 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Страница 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Страница 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Страница 134: ......

Страница 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Страница 147: ...E 01 13 E_01_GB fm 13 18 3 1 Mounting extension parts Sch_ver1 tif Sch_ver2 tif 16 5 9 10 8 7 6 14 15 12 11 12 5...

Страница 152: ......

Страница 154: ......

Страница 155: ...F_2 3_01_GB fm 1 2 F 2 3 1 F 2 3 Maintenance overview 1 Maintenance review 7 2 4 1 3 5 1 6 8 9 10...

Страница 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Страница 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Страница 168: ......

Страница 180: ......

Страница 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Страница 189: ...F 7 2 1 F_7 2_01_GB fm 1 4 F 7 2 Maintenance Running gear 1 Maintenance running gear 635_ISO_Dyn bmp LW_DEM_inter bmp 43...

Страница 193: ...F 8 1 1 F_8 1_01_GB fm 1 20 F 8 1 Maintenance Electronic System 1 Maintenance Electronic System...

Страница 220: ......

Страница 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Страница 226: ......