D 4.6 32

D_4

.6_0

1_G

B.

fm

3

2

-3

8

2.5

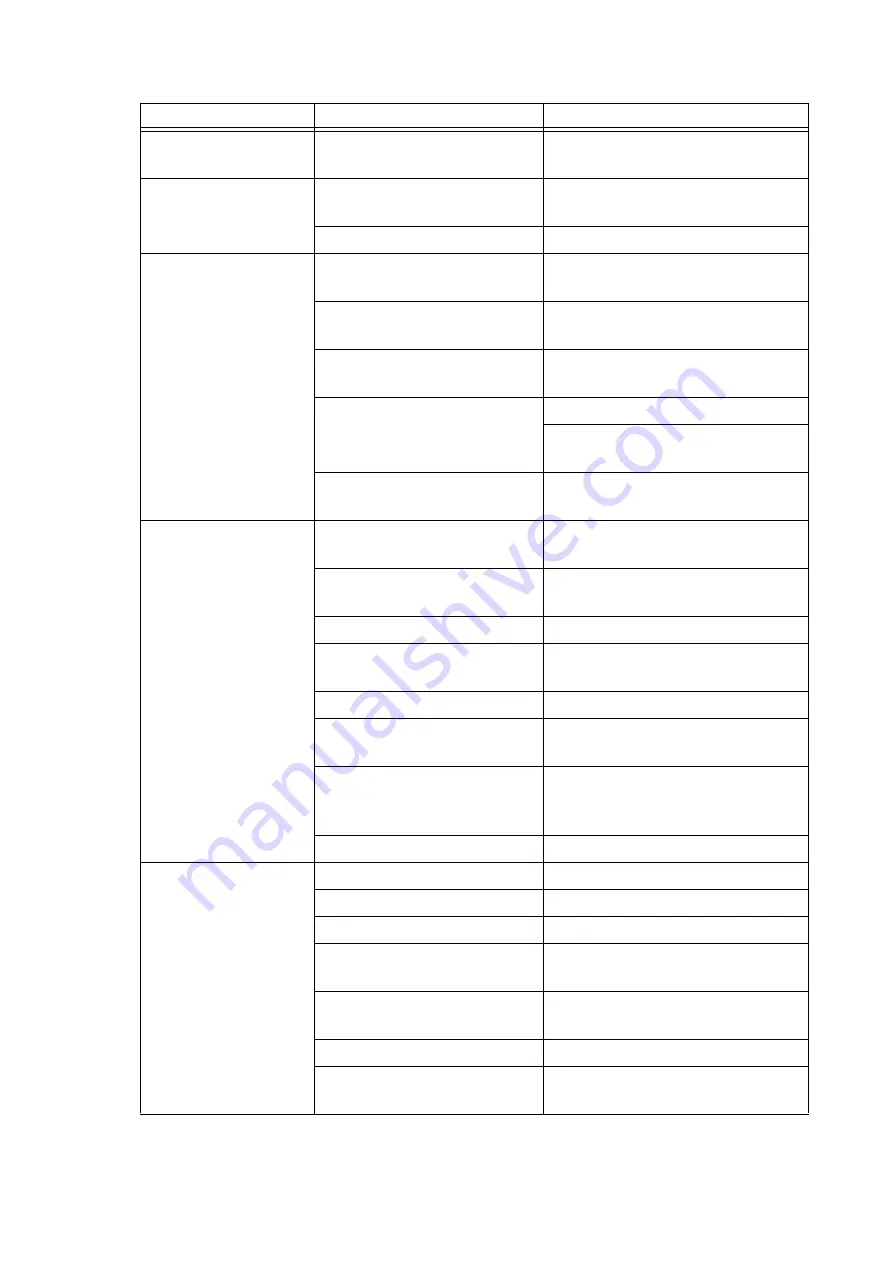

Malfunctions on the paver finisher or screed

Malfunction

Cause:

Remedy

At the diesel engine

Diverse

See operating instructions for

the engine

Diesel engine does

not start

Batteries empty

See ”External starting”

(start assistance)

Diverse

see ”Towing”

Tamper or vibration

does not operate

Tamper is obstructed by

cold bitumen

Properly heat the screed

Hydraulic oil level in the

tank is too low

Top up the oil

Pressure limiting valve is

defective

Replace the valve; if necessary,

repair and adjust the valve

Leak in the suction line of

the pump

Seal or replace the connections

Tighten or replace the hose

clamps

Oil filter is soiled

Clean the filter; if necessary,

replace the filter

Conveyor or augers

run too slowly

Hydraulic oil level in the

tank is too low.

Top up the oil

Power supply is interrupted

Check fuses and cables; replace

if necessary

Switch is defective

Replace the switch

One of the pressure limit-

ing valves is defective

Repair or exchange the valves

Pump shaft broken

Replace the pump

Limit switch does not switch

or regulate correctly

Check the switch; replace and

adjust the switch if necessary

Pump is defective

Check the high pressure filter for

dirt particles; replace if neces-

sary

Oil filter is soiled

Replace the filter

Hopper cannot be

swung open

Engine speed is too low

Increase the speed

Hydraulic oil level is too low Top up the oil

Leak in the suction line

Tighten the connections

Flow rate regulator

defective

Replace

Leaking seals of the

hydraulic cylinder

Replace

Control valve is defective

Replace

Power supply interrupted

Check fuse and cables; replace

if necessary

Содержание DYNAPAC Svedala Demag DF 115 C

Страница 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Страница 10: ......

Страница 18: ......

Страница 20: ......

Страница 44: ......

Страница 58: ......

Страница 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Страница 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Страница 66: ...D 1 4 8 D_1 4_01_GB fm 8 22 Element2_konv_Kette_635 bmp 27 19 18 17 28 29 B 16 25 26 22 21 20 23 24...

Страница 68: ...D 1 4 10 D_1 4_01_GB fm 10 22 Element2_konv_Kette_635 bmp 27 19 18 17 28 29 B 16 25 26 22 21 20 23 24...

Страница 70: ...D 1 4 12 D_1 4_01_GB fm 12 22 Element2_konv_Kette_635 bmp 27 19 18 17 28 29 B 16 25 26 22 21 20 23 24...

Страница 96: ......

Страница 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Страница 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Страница 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Страница 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Страница 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Страница 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Страница 134: ......

Страница 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Страница 147: ...E 01 13 E_01_GB fm 13 18 3 1 Mounting extension parts Sch_ver1 tif Sch_ver2 tif 16 5 9 10 8 7 6 14 15 12 11 12 5...

Страница 152: ......

Страница 154: ......

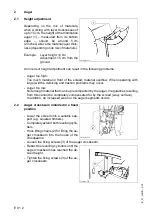

Страница 155: ...F_2 3_01_GB fm 1 2 F 2 3 1 F 2 3 Maintenance overview 1 Maintenance review 7 2 4 1 3 5 1 6 8 9 10...

Страница 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

Страница 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Страница 168: ......

Страница 180: ......

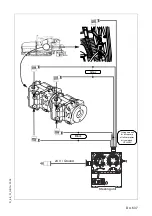

Страница 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Страница 189: ...F 7 2 1 F_7 2_01_GB fm 1 4 F 7 2 Maintenance Running gear 1 Maintenance running gear 635_ISO_Dyn bmp LW_DEM_inter bmp 43...

Страница 193: ...F 8 1 1 F_8 1_01_GB fm 1 20 F 8 1 Maintenance Electronic System 1 Maintenance Electronic System...

Страница 220: ......

Страница 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Страница 226: ......