E 01 2

E_0

1_G

B.

fm

. 2-

18

2

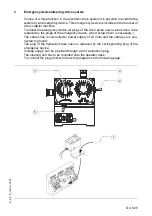

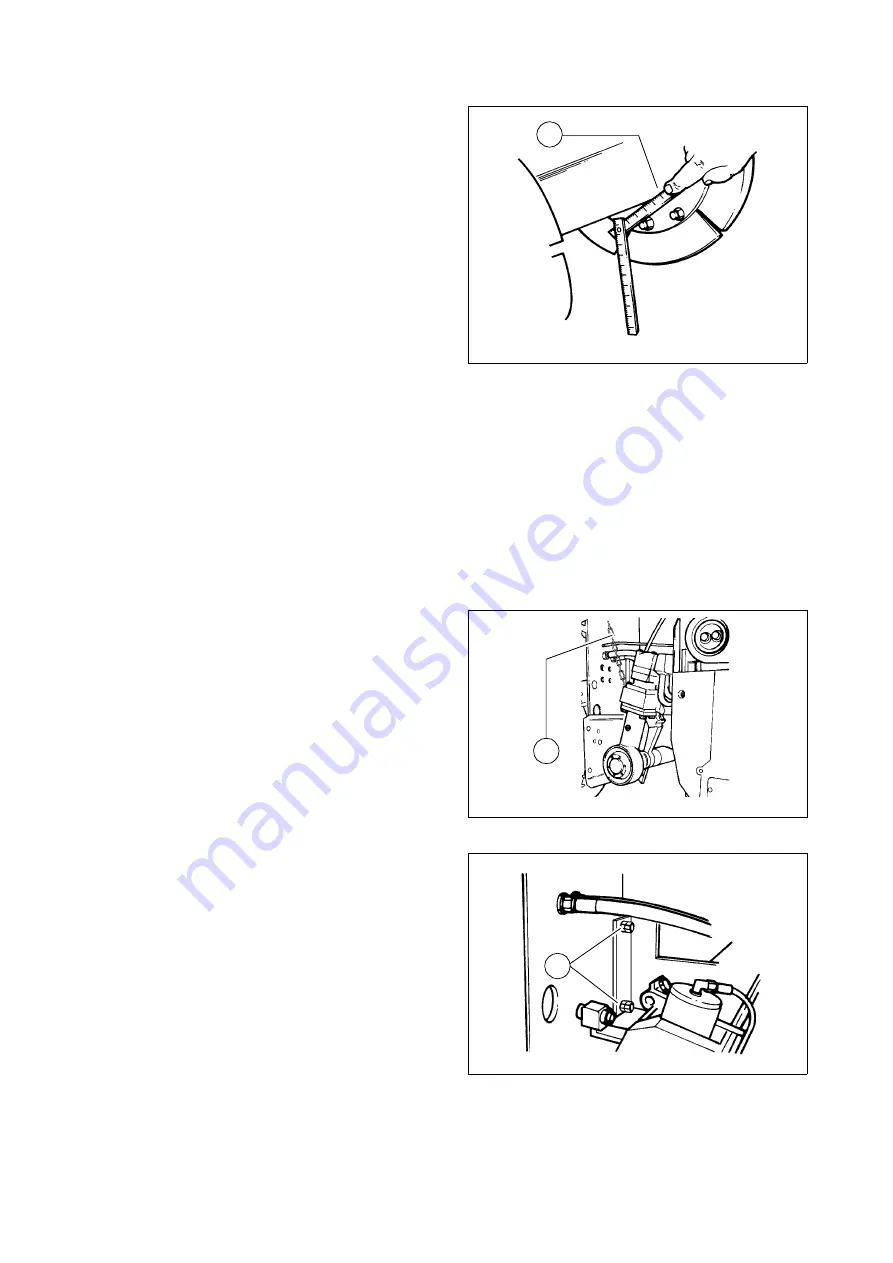

Auger

2.1

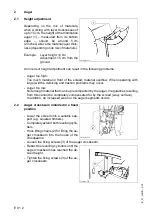

Height adjustment

Depending on the mix of materials,

when working with layer thicknesses of

up to 15 cm, the height of the distribution

auger (1) – measured from its bottom

edge – should be around 5 cm

(2 inches) above the material layer thick-

ness (depending on its mix of materials).

Example: Layer height 10 cm

Adjustment: 15 cm from the

ground

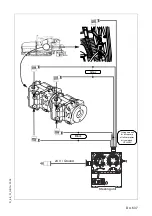

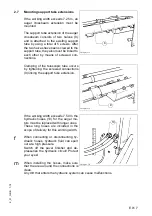

An incorrect height adjustment can result in the following problems:

- Auger too high:

Too much material in front of the screed; material overflow. When operating with

larger widths, demixing and traction problems may occur.

- Auger too low:

Not enough material that can be precompacted by the auger. Irregularities resulting

from this cannot be completely compensated for by the screed (wavy surface).

In addition, an increased wear on the auger segments occurs.

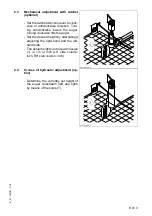

2.2

Auger crossbeam installed in a fixed

position

- Lower the screed onto a suitable sup-

port (e.g. squared timbers).

- Completely extend both levelling cylin-

ders.

- Hook lifting chains (2) for lifting the au-

ger crossbeam into the hooks of the

crossbeams.

- Loosen the fixing screws (3) of the auger crossbeam.

- Retract the levelling cylinders until the

auger crossbeam has reached the de-

sired height.

- Tighten the fixing screws (3) of the au-

ger crossbeam.

F0130_A1.TIF

1

F0131_A1.TIF

2

F129_A1.TIF

3

Содержание DYNAPAC Svedala Demag DF 115 C

Страница 2: ...VALUE QUALITY THE ORIGINAL Your Authorized Dynapac Dealer...

Страница 10: ......

Страница 18: ......

Страница 20: ......

Страница 44: ......

Страница 58: ......

Страница 62: ...D 1 4 4 D_1 4_01_GB fm 4 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Страница 64: ...D 1 4 6 D_1 4_01_GB fm 6 22 Element2_konv_Kette_635 bmp 9 12 9a 5 8 14 A 6 7 13...

Страница 66: ...D 1 4 8 D_1 4_01_GB fm 8 22 Element2_konv_Kette_635 bmp 27 19 18 17 28 29 B 16 25 26 22 21 20 23 24...

Страница 68: ...D 1 4 10 D_1 4_01_GB fm 10 22 Element2_konv_Kette_635 bmp 27 19 18 17 28 29 B 16 25 26 22 21 20 23 24...

Страница 70: ...D 1 4 12 D_1 4_01_GB fm 12 22 Element2_konv_Kette_635 bmp 27 19 18 17 28 29 B 16 25 26 22 21 20 23 24...

Страница 96: ......

Страница 120: ...D 4 6 24 D_4 6_01_GB fm 24 38 2 2 Error messages...

Страница 121: ...D 4 6 25 D_4 6_01_GB fm 25 38...

Страница 122: ...D 4 6 26 D_4 6_01_GB fm 26 38...

Страница 123: ...D 4 6 27 D_4 6_01_GB fm 27 38...

Страница 124: ...D 4 6 28 D_4 6_01_GB fm 28 38...

Страница 125: ...D 4 6 29 D_4 6_01_GB fm 29 38 2 3 FMI codes...

Страница 134: ......

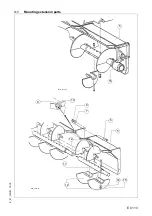

Страница 146: ...E 01 12 E_01_GB fm 12 18 3 Auger extension auger type II Auger_DEM bmp...

Страница 147: ...E 01 13 E_01_GB fm 13 18 3 1 Mounting extension parts Sch_ver1 tif Sch_ver2 tif 16 5 9 10 8 7 6 14 15 12 11 12 5...

Страница 152: ......

Страница 154: ......

Страница 155: ...F_2 3_01_GB fm 1 2 F 2 3 1 F 2 3 Maintenance overview 1 Maintenance review 7 2 4 1 3 5 1 6 8 9 10...

Страница 157: ...F 3 0 1 F_3 0_01_GB fm 1 4 F 3 0 Maintenance Conveyor 1 Maintenance Conveyor...

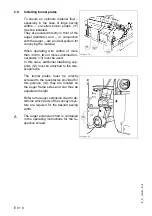

Страница 161: ...F 4 1 1 F_4 1_01_GB fm 1 8 F 4 1 Maintenance Auger 1 Maintenance auger sub unit...

Страница 168: ......

Страница 180: ......

Страница 181: ...F 6 0 1 F_6 0_01_GB fm 1 8 F 6 0 Maintenance Hydraulic system 1 Maintenance hydraulic system...

Страница 189: ...F 7 2 1 F_7 2_01_GB fm 1 4 F 7 2 Maintenance Running gear 1 Maintenance running gear 635_ISO_Dyn bmp LW_DEM_inter bmp 43...

Страница 193: ...F 8 1 1 F_8 1_01_GB fm 1 20 F 8 1 Maintenance Electronic System 1 Maintenance Electronic System...

Страница 220: ......

Страница 221: ...F 10 0 1 F_10 0_01_GB fm 1 6 F 10 0 Checks decommissioning 1 Tests check up cleaning stopping...

Страница 226: ......