56

4. The pump should operate (it would be heard run-

ning).

NOTE: If the fuel pump fails to operate, the pump

is defective and must be replaced.

Fuel Pressure Regulator

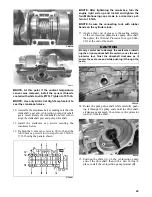

1. Using the EFI Fuel Pressure Test Kit (p/n 0644-

571), connect the tester to the delivery pipe and

gasline hose.

AO053

NOTE: A short piece of 3/8 in. I.D. hose will be

needed for this procedure.

2. Pressurize the regulator to 2.0-2.2 kg/cm² (28-31.3

psi). Turn the pressure tester shut off valve to the

OFF position. Observe the gauge for several min-

utes and note any loss of pressure. If pressure

begins to drop, the cause may be a ruptured dia-

phragm, worn spring, or leaking valve. If the regu-

lator fails to build or maintain pressure, the fuel

pump assembly must be replaced.

NOTE: If the pressure drops, check the hose con-

nections to ensure no leaks exist.

Testing Coolant Temperature

Sensor Resistance

NOTE: The coolant temperature sensor is very

sensitive to temperature change. Before the resis-

tance test is conducted, the coolant temperature

must be known. If the engine has been operated

recently and the coolant is warm, the resistance

will measure lower than if the coolant was at room

temperature or colder. For accurate test results,

check the coolant temperature in the filler neck

using a thermometer.

1. Disconnect the coolant temperature sensor wiring

harness from the main harness.

2. Set the meter selector to the OHMS position and

test the resistance between the two leads from the

sensor.

3. Compare the resistance reading to the Voltage/

Resistance Chart - Coolant Temperature in this

manual. If resistance is not within the specifica-

tion, replace the sensor.

NOTE: A coolant temperature sensor voltage test

can be made using the EFI Analyzer.

NOTE: The coolant temperature sensor is located

at the lower half of the crankcase. To remove the

sensor, the engine must be removed.

Testing Air Temperature Sensor

Resistance

NOTE: The component temperature must be

known before conducting this test. Allow the

engine to reach room temperature.

1. Disconnect the wiring harness from the air temper-

ature sensor.

AO135D

2. Set the meter selector in the OHMS position and

test the two leads located in the sensor connector.

Compare with the Voltage/Resistance Chart - Air

Temperature in this manual.

NOTE: The air temperature sensor utilizes a therm-

istor, which is very sensitive to temperature changes.

Resistance will change as temperature varies.

Removing Air Temperature Sensor

1. Disconnect the wiring harness from the air temper-

ature sensor.

2. Using a standard screwdriver, pry the sensor end

to end to remove it from the air silencer. Account

for two push pins.

Installing Air Temperature Sensor

1. Place the sensor into position in the air silencer

and secure with push pins.

2. Connect the wiring harness to the air temperature

sensor. Secure the sensor leads with cable ties so

they do not rub on any other components.

WARNING

Since the fuel supply hose may be under pressure, remove

it slowly to release the pressure. Place an absorbent

towel around the connection to absorb gasoline; then

remove the hose slowly to release the pressure. Always

wear safety glasses when removing the fuel hoses.

Содержание 2014 SNO PRO 500

Страница 1: ...SNO PRO 500 ...

Страница 16: ...12 Wiring Diagram Hood Harness p n 1686 587 0744 201 ...

Страница 17: ...Wiring Diagram Ignition Main Harness p n 1686 628 0745 605 13 ...

Страница 18: ...14 NOTES ...

Страница 89: ......

Страница 90: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2259 778 ...