26

The ECM is the brain of the EFI system. It uses sensor

inputs to determine the correct fuel/air ratio for the

engine given the existing conditions of altitude and

temperature.

If any of the sensors should fail while the engine is

running, the ECM will sense a problem and go into a

“fail safe” mode. This is an over-rich condition and

will greatly reduce performance. However, the engine

will be protected from a possible lean condition and

engine damage.

The ECM is equipped with a self-diagnostic system

utilizing the service icon in the speedometer/tachome-

ter and remains illuminated when a problem exists

with any of the sensors. The technician can determine

the problem sensor by reading the code shown on the

readout screen and applying it to the Diagnostic Codes

chart.

NOTE: The ECM cannot be repaired.

If the ECM is not receiving current from one of the

output coils on the stator, that circuit will not operate.

Coils on the stator are the charge coils operating the

ECM, the injector coil which operates the injectors,

the fuel pump coil which operates the fuel pump, and

the lighting coil operating all accessories and the light-

ing system.

Air Temperature Sensor

This sensor detects air temperature entering the air

silencer and engine. The ECM sends current to this

sensor, and (depending on the temperature) the sensor

will pass a certain amount of current through the sen-

sor to ground. The ECM measures how much current

passes through the sensor to ground. From this mea-

surement, the ECM determines the air temperature and

calculates the fuel/air mixture ratio. This sensor is very

sensitive to temperature change. Resistance will drop

as the temperature rises.

Coolant Temperature Sensor

This sensor is very sensitive to temperature change.

The ECM measures the current flow through the sen-

sor to ground. From this measurement, the ECM can

determine the engine coolant temperature and calcu-

late the correct fuel/air mixture ratio.

NOTE: If the coolant temperature rises above

80° C (176° F), the temperature sensor starts to

richen the fuel mixture. At this time, the check

engine light will flash constantly. Once the engine

coolant temperature reaches the specified temper-

ature 93° C (200° F), the temperature sensor will

signal the ECM to go into the rich mode to protect

the engine from overheating. At this time, the

check engine light will stay on.

Throttle Position Sensor

This sensor, located at the end of the throttle shaft, is a

potentiometer (essentially, a resistor). This sensor

transforms the throttle-valve position into output volt-

age to the ECM. In addition, the sensor detects the

opening or closing speed of the throttle valve and

feeds that rate of voltage change to the ECM.

NOTE: The input from the throttle position sen-

sor is one of the main inputs for the ECM calcula-

tion of fuel/air mixture ratio.

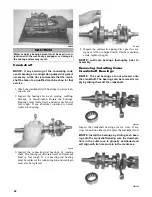

Ignition Timing Sensor

This sensor is located inside the magneto case next to

the flywheel, and the recoil starter and the flywheel

must be removed to access the sensor. This sensor is

triggered by a small metal disc precisely mounted to

the flywheel flange. Each time the disc rotates past the

sensor, a signal is sent to the ECM. From this signal,

the ECM determines ignition and injection timing and

RPM.

Barometric Pressure Sensor

This sensor is located inside the ECM and is part of the

ECM unit. Its purpose is to sense atmospheric pres-

sure. From this information, the ECM determines the

correct fuel/air mixture ratio.

NOTE: This sensor is not replaceable. If it should

fail, the ECM must be replaced.

Fuel Injectors

The fuel injectors are positioned in the top of each

throttle body.

A fuel injector is an electromagnetic injection valve

controlled by a signal from the ECM. The coil used in

the injector is a high-pressure resistance type. The

ECM determines the optimum fuel injection time and

duration based on signals from the five sensors.

When voltage is sent to the fuel injector, it energizes

the coil and opens the needle valve, thereby injecting

fuel. Because the fuel pressure (pressure differential

between fuel line and manifold) is kept constant, the

amount of fuel injected is determined by the duration

of time the valve is open.

The injectors are coded with letters (A-B-C). When

replacement of a fuel injector is necessary, the injector

must be replaced with an injector of the same code letter.

CAUTION

Do not replace an injector with one of a different letter.

Severe engine damage may occur.

Содержание 2014 SNO PRO 500

Страница 1: ...SNO PRO 500 ...

Страница 16: ...12 Wiring Diagram Hood Harness p n 1686 587 0744 201 ...

Страница 17: ...Wiring Diagram Ignition Main Harness p n 1686 628 0745 605 13 ...

Страница 18: ...14 NOTES ...

Страница 89: ......

Страница 90: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2259 778 ...