39

Cylinders

1. Using a non-metallic carbon removal tool, remove

carbon buildup from the exhaust ports.

2. Wash the cylinders in parts-cleaning solvent.

3. Inspect the cylinders for pitting, scoring, scuffing,

and corrosion. If marks are found, repair the sur-

face with a Ball Hone (p/n 0644-292) and honing

oil.

NOTE: To produce the proper 45° crosshatch pat-

tern, maintain a low drill RPM. If honing oil is not

available, use a lightweight, petroleum-based oil.

Thoroughly clean the cylinders after honing using

detergent soap and hot water and dry with com-

pressed air; then immediately apply oil to the cyl-

inder bores. If a bore is severely damaged or

gouged, the cylinder must be replaced.

4. Place the head surface of each cylinder on the sur-

face plate covered with #400 grit wet-or-dry sand-

paper. Using light pressure, move each cylinder in

a figure eight motion. Inspect the surface for any

indication of high spots. A high spot can be noted

by a bright metallic finish. Correct any high spots

before assembly by continuing to move the cylin-

der in a figure eight motion until a uniform bright

metallic finish is attained.

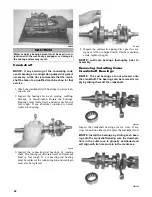

Piston Assembly

1. Using a non-metallic carbon removal tool, remove

the carbon buildup from the dome of each piston.

2. Snap an old piston ring into two pieces; then grind

the end of the old ring to a 45° angle and to a sharp

edge. Using the sharpened ring as a tool, clean car-

bon from the ring-grooves. Be sure to position the

ring with its tapered side up.

3. Inspect each piston for cracks in the piston pin and

skirt areas.

4. Inspect each piston for seizure marks or scuffing.

Repair with #400 grit wet-or-dry sandpaper and

water or honing oil.

AN135

NOTE: If scuffing or seizure marks are too deep

to correct with the sandpaper, it will be necessary

to replace the piston.

5. Inspect the perimeter of each piston for signs of

excessive “blowby.” Excessive “blowby” indicates

worn piston rings or an out-of-round cylinder.

NOTE: If synthetic oil is being used, a certain

amount of “blowby” may be visible under normal

use.

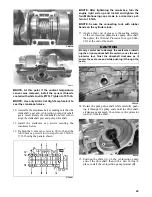

Crankcase

1. Wash the crankcase halves in parts-cleaning sol-

vent.

NOTE: Before washing the crankcase halves,

make sure the four bearing dowel pins have been

removed and accounted for.

2. Inspect the crankcase halves for scoring, pitting,

scuffing, or any imperfections in the casting.

3. Inspect all threaded areas for damaged or stripped

threads.

4. Inspect the bearing areas for cracks or excessive

bearing movement. If evidence of excessive bear-

ing movement is noted, the crankcase must be

replaced.

5. Inspect the bearing dowel pins for wear.

6. Inspect the sealing surfaces of the crankcase

halves for trueness by placing each crankcase half

on the surface plate covered with #400 grit wet-or-

dry sandpaper. Using light pressure, move each

half in a figure eight motion. Inspect the sealing

surfaces for any indication of high spots. A high

spot can be noted by a bright metallic finish. Cor-

rect any high spots by continuing to move the half

in a figure eight motion until a uniform bright

metallic finish is attained.

NOTE: Care must be taken not to remove an

excessive amount of aluminum, or the crankcase

must be replaced. If excessive aluminum is

removed, too much pre-load will be exerted on the

crankshaft bearings when assembled.

CAUTION

Water or parts-cleaning solvent must be used in con-

junction with the wet-or-dry sandpaper or damage to

the sealing surface may result.

CAUTION

Improper cleaning of the ring-grooves by the use of

the wrong type of ring-groove cleaner will result in

severe damage to the piston.

Содержание 2014 SNO PRO 500

Страница 1: ...SNO PRO 500 ...

Страница 16: ...12 Wiring Diagram Hood Harness p n 1686 587 0744 201 ...

Страница 17: ...Wiring Diagram Ignition Main Harness p n 1686 628 0745 605 13 ...

Страница 18: ...14 NOTES ...

Страница 89: ......

Страница 90: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2259 778 ...