59

Removing Oil-injection Pump

NOTE: To service the oil-injection pump, the

exhaust system and the air silencer must be

removed.

1. Remove the throttle bodies and secure them out of

the way in an upright position.

2. Disconnect the oil-supply hose from the pump and

plug to prevent oil drainage.

3. Remove the oil-delivery hoses from the intake

flanges.

4. Disconnect the oil-injection cable.

5. Remove the two screws securing the oil-injection

pump and retainer to the crankcase.

6. Pull the oil-injection pump away from the retainer/

crankcase and account for a gasket/O-ring.

NOTE: Remove the oil-injection pump from the

crankcase only if the O-ring or gasket need to be

replaced.

7. Turn the pump sideways; then remove the lower

union bolt. Account for two washer gaskets.

Remove the pump.

8. Remove the remaining union bolts securing the

check valves to the pump. Account for the washer

gaskets.

9. Remove the check valves. Account for two gaskets.

Installing Oil-injection Pump

1. In turn on each front union bolt, install a washer

gasket, check valve, and washer gasket; then

install on the oil-injection pump.

2. Place the gasket and oil-injection pump near the

engine; then install the lower union bolt through a

gasket, check valve, and gasket.

3. Position the oil-injection pump on the engine mak-

ing sure the oil-injection pump gear is correctly

aligned with the oil-injection pump drive gear.

4. Secure the pump with two screws (coated with

blue Loctite #243). Tighten screws to 96 in.-lb.

5. Connect the oil-delivery hoses to the intake

flanges. Secure with clamps.

6. Connect the oil-injection cable to the pump and

secure.

7. Connect the oil-supply hose to the oil-injection

pump inlet fitting. Secure with the clamp.

8. Bleed the oil-injection system.

9. Check the oil-injection system synchronization

(see Synchronizing Oil-Injection Pump). Tighten

the jam nuts securely.

NOTE: Install the exhaust system and the air

silencer.

10. Install the throttle bodies.

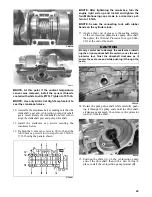

Inspecting/Adjusting/

Synchronizing Oil-injection Pump

S

742-331A

1. With the engine off, disconnect the throttle cable

from the throttle lever.

2. Pull the throttle cable to the FULL-OPEN posi-

tion; then using a suitable clamping device, secure

the cable in this position.

3. Check to be sure the mark on the control arm is

aligned with alignment mark on the oil pump boss.

4. If the marks are not aligned, adjust synchroniza-

tion by loosening the jam nut(s) on the adjuster.

Rotate the jam nuts/adjuster nut until proper align-

ment is attained. Tighten jam nut(s).

5. Return the throttle cable to the CLOSED position.

NOTE: Connect the throttle cable to the throttle

lever; then adjust the cable adjusting nut so the

throttle lever moves approximately 1/8 in. before

the oil-injection pump control arm begins to move.

This ensures the throttle/ignition monitor switch

will function properly and will prevent ignition

“cut-out” and spark plug fouling at low RPM oper-

ation.

CAUTION

Care must be taken when securing the cable not to

kink or damage the cable.

CAUTION

Assure that the throttle cable has returned to the fully

closed (idle) position and has not remained in a partial

open position and moves freely from the open posi-

tion to the closed position.

Содержание 2014 SNO PRO 500

Страница 1: ...SNO PRO 500 ...

Страница 16: ...12 Wiring Diagram Hood Harness p n 1686 587 0744 201 ...

Страница 17: ...Wiring Diagram Ignition Main Harness p n 1686 628 0745 605 13 ...

Страница 18: ...14 NOTES ...

Страница 89: ......

Страница 90: ...Printed in U S A Trademarks of Arctic Cat Inc Thief River Falls MN 56701 p n 2259 778 ...