Antti-Teollisuus Oy

18

408102 02-2020

Vacboost WM09

Dryer Heater

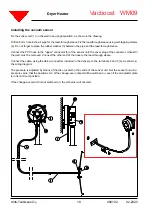

To be observed before starting the operation

- The oil burner fitter and the electrician have completed the test run.

- The operation of the safety devices needs to be tested in practice to ensure their proper operation.

- Gas is being supplied to the burner.

- There are no objects in the heater room that do not belong there.

- That exclusively clean air is sucked through the heater.

- The shut-off valves in the oil pipes are in the open-position.

- Check once more that the main switches and possible safety switches are in the operating position.

- That there is a fire extinguisher outside the heater room during the drying process.

- Make sure that the slab in front and at both sides of the suction nets of the heater is clean and, for example,

the wind cannot blow debris or withered plants near to the suction cone opening of the heater.

OPERATING INSTRUCTIONS FOR THE DRYER HEATER

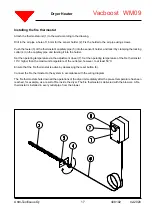

- In dryers equipped with axial blowers, the drying air flow is restricted, as necessary, by reducing the rotation

speed of the blower by means of a frequency converter.

In dryers equipped with radial blowers, the drying air flow is restricted, as necessary, by means of the adjust

-

ment flap in the outlet air pipes. The flap shall be located between the dryer and the blower.

WARNING! Before opening the burner, make sure that it is tensionless. High tension inside the burner.

Risk of fatal electric shock.

- When passing from the drying stage to the cooling stage after the drying, the thermostat of the drying automa-

tion stops the burner automatically as soon as the pre-set outlet temperature, i.e. the cut-off point, has been

reached (if the heater is connected to an automatic centre).

- The heater fan cannot be switched off even via its own operating switch before the heater has cooled down

below the "fan” temperature of the LTM thermostat (nor shall the heater blower be switched off from the main

switch until the heater has cooled down).