PRE-INSTALLATION GUIDELINES (Continued)

2. Do not install the linear detection wire within 12 in. (30 cm) of

areas which will become extremely hot during operation, such

as engine block, exhaust manifolds, turbochargers. etc.

Note: Maximum installed ambient temperature at the wire

location is 221 °F (105 °C).

3. Avoid routing detection wire directly across an opening.

Where possible, install detection wire above the hazard area

or around the perimeter of a hazard compartment to react to

escaping heat. Do not allow struts, frame members, etc. to act

as heat shields between the hazard and the detection wire.

4. Avoid areas where the detection wire may be damaged, such

as outside the vehicle, near moving parts, in areas where

rocks or debris may be thrown by wheels, or in the way of

maintenance personnel.

5. To reduce its accessibility to damage, use only as much

detection wire as is necessary to cover the hazard area.

6. The minimum bend radius for detection wire must not be less

than 2 1/2 in. (65 mm).

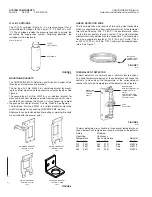

Thermal Spot Detector Selection and Placement

Thermal detectors are used when single point detection is

required. They are selected by temperature range relative to the

hazard temperature. Table 1 indicates the thermal spot detector

rated operating temperature required according to the maximum

hazard temperatures.

Thermal Spot

Detector

Maximum

Rated Operating

Hazard

Temperature Temperature

Detector

°F

(°C)

°F

(°C)

Color

Part No.

_____________

___________

____

_______

270

(132)

234

(112)

Blue

416218

325

(163)

280

(137)

Red

416219

360

(182)

312

(155)

Red

416220

TABLE 1

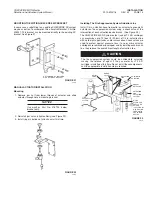

The placement of thermal spot detectors should be based on the

following requirements:

1. They can be wired directly to the control module using

approved cable. Cable must have a temperature rating of

392 °F (200 °C) minimum, 16-18 gauge, two conductor with

drain, minimum O.D. of 0.230 in. (5.8 mm). Again, placement

of the detectors should allow for incoming and outgoing wire

connections.

2. Secure the detector with the provided bracket and clamps.

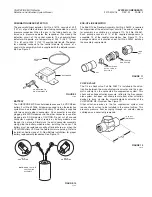

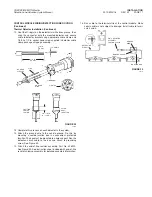

Pneumatic/Linear Detection Tubing

1. When mounting tubing and responder, make certain they are

not in areas subject to damage.

2. Avoid routing detection tubing directly across an opening.

Where possible, install detection tubing above the hazard

area or around the perimeter of a hazard compartment to

react to escaping heat. Do not allow struts, frame members,

etc., to act as heat shields between the hazard and the detec-

tion tubing.

3. The detection tubing assembly is 35 ft (10.7 m) long. If more

than 35 ft (10.7 m) is required, additional assemblies can be

added. See wiring diagram details on instruction sheet

included with each Pneumatic/Linear Detection Shipping

Assembly.

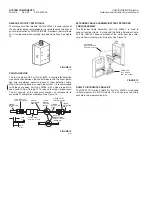

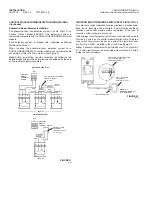

System Layout

Once the system components have been selected and their loca-

tions have been determined, sketch the layout of the system. This

sketch should include the location of the components, as well as

the proposed detection wire routing, thermal detector locations,

and pneumatic actuation hose routing. Also, indicate areas where

the wire must pass through bulkheads so that there is an accept-

able routing from one hazard to the next. This sketch should be as

precise as possible to avoid any unforeseen installation problems

later.

SYSTEM PLANNING

2012-MAY-18 REV. 02 PAGE 11

CHECKFIRE MP-N Electric

Detection and Actuation System Manual