HAZARD IDENTIFICATION

Before the CHECKFIRE MP-N Electric Detection and Actuation

System is installed, the hazards to be protected must be identified.

These hazard locations determine where the detection wire or

thermal detectors and the fire suppression system nozzles are

required. While the agent nozzles in existing fire suppression

systems will point out the hazard areas, the following information

should still be reviewed to best determine detection requirements.

If an entire fire suppression/detection system is to be installed, this

information is vital in determining proper placement of discharge

nozzles and detection devices.

Fire Hazard Definition

A fire hazard is any area where an ignition source (high tempera-

ture or sparks) and fuel (flammable materials) may be found in

close proximity.

Examples of ignition sources are engines, exhaust piping,

turbochargers, battery compartments, electrical system equip-

ment, torque converters, transmissions, hydraulic pumps, parking

brakes, and friction from debris packed around parts.

Occasionally other components may reach high temperatures due

to malfunction. The potential danger from these components must

also be examined during hazard identification. A parking brake left

engaged is an example of a potential high temperature source.

Temperatures in excess of the detection wire or thermal detector

ratings will cause the detection system to activate thereby actuat-

ing the fire suppression system.

The above mentioned heat sources can cause fire when they

come in contact with flammable materials such as leaking fuel:

either broken fuel lines, slow leaks, broken hydraulic lines, or a

ruptured fuel tank. Type of Class A materials are part of the vehicle

itself such as electric wiring insulation, padding, plastic parts, the

packages on the vehicle, or debris due to poor maintenance.

These materials can contribute to the rapid buildup or spreading

of fire.

Other Considerations

Be aware that the propagation of fire from one area to another

may cause a hazard to be larger than originally determined. Liquid

fuel may spray, splash, or flow carrying the fire some distance

from the starting point. Radiation, sparks, or conduction through

metal can carry heat to an area where the danger of fire wouldnʼt

normally exist.

Also, consider the fire history of the equipment being protected or

of similar equipment. This information may be available through

company records or vehicle operators may have had first hand

experience enabling them to identify the locations of previous fires

as well as special hazards such as a hydraulic hose that frequently

ruptures.

Each hazard that is identified must have both fire suppression

system fixed nozzles and detection wire or thermal detectors.

Equipment Shutdown

Another factor to examine is equipment shutdown. Provisions

should be made to shut down any components that could possibly

add to the intensity of the fire (fuel pumps, hydraulic pumps,

engine, etc.) or any components that could possibly re-ignite the

fire once it has been suppressed (battery, electrical system).

Although a properly installed fire suppression/detection system is

the primary means of protecting equipment from fire, an effective

fire protection package also includes provisions for equipment

shutdown.

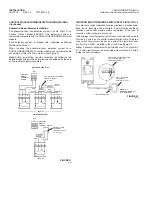

The CHECKFIRE MP-N control module contains 3 amp 30VDC

shutdown relay contacts to facilitate connection of shutdown

devices recommended by the vehicle manufacturer. Example:

opening or closing of coolant over-temperature alarm will bring

about properly sequenced engine shutdown on many vehicles.

Consult vehicle manufacturer for details.

PRE-INSTALLATION GUIDELINES

Before actually installing the CHECKFIRE MP-N Electric

Detection and Actuation System, review all of the following infor-

mation and plan (sketch) the system layout. This will help to avoid

any unforeseen installation problems. Once an acceptable layout

has been determined, record and keep it for future reference.

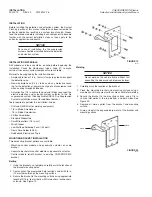

Control Module and Actuator Location

1. The control module and manual actuator must be mounted in

the cab or control area of the equipment being protected.

They must be positioned within arms reach of the operator to

enable manual operation of the red strike button on the

manual actuator as well as the delay and reset buttons (to

extend time delay) on the front of the control module, and

close enough so that the internal alarm can be heard.

2. The location must be suitable for bolting or welding if bolting is

impractical. The mounting surface must be flat to avoid strain on

the mounting bracket. The preferred mounting position is with

the CHECKFIRE MP-N control module in an upright position.

3. There must be room enough to allow for proper wiring

connection to the control module and to install the actuation

line from the fire suppression system to the manual actuator.

Also, the module and actuator should be accessible for peri-

odic inspection and maintenance. The components should be

mounted in a location that will not interfere with normal equip-

ment maintenance.

NOTICE

The ambient temperature in the mounting

environment must not fall below –40 °F

nor exceed 140 °F (–40 to 60 °C).

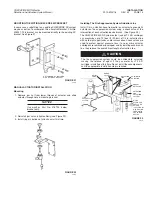

4. The gas motor actuator can be mounted in any convenient

location within 10 ft. (3.1 m) of the module, which is not

subject to damage or abuse. The gas motor actuator bracket

can be welded or bolted to a rigid surface.

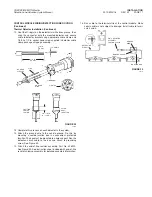

Detection Wire Routing

The preferred method for routing linear detection wire is to begin

by connecting the detection wire directly to the CHECKFIRE MP-N

control module.

Because linear detection wire need only be routed through the

hazard area, another acceptable routing method is to use

stranded 16 AWG jacketed wiring connected to the control module

and routed to the beginning of the hazard area(s). At that point, a

splicing device, Part No. 428375, can be used to make the proper

connection between the stranded 16 AWG jacketed wire and the

start of the linear detection wire.

This method can only be used

when the splicing device can be adequately protected from

damage and moisture.

1. The total length of detection wire must not exceed 100 ft.

(30.5 m). If possible, it should be run in a single continuous

loop. Splices are acceptable when they are kept to a minimum

and when they are made in accordance with the splicing tech-

nique found on Page 15 of Installation Section.

SYSTEM PLANNING

PAGE 10

REV. 02 2012-MAY-18

CHECKFIRE MP-N Electric

Detection and Actuation System Manual