5

Amphenol Network Solutions

All rights reserved. 12.18.19 139688-3

509.926.6000 – amphenol-ns.com

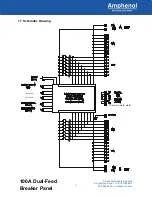

100A Dual-Feed

Breaker Panel

3. For ground wiring, use a listed (approved) crimping tool to

attach a listed (approved), single- or dual-hole compression

lug onto suitable ground wire. (Use #10 AWG to #6 AWG,

depending on input interruption device.)

4. Use a coarse, nonmetallic cleaning pad to clean terminals

and stud(s).

5. Amphenol Network Solutions recommends that you lightly

coat antioxidant on the lug, grounding terminal and

surrounding contacting surface.Connect the lug to the stud

using an M5 washer and nut from the terminal, as shown in

Figure 4. Tighten the nut to 20 in.-lb (~2.25 N

•

m), max.,

using an 8-mm (5/16 in.) socket.

WARNING! Before connecting input power cables, make sure input power to the panel is

turned off.

6. Make sure the input power is off.

7. For input wiring, — wiring used as inputs to this distribution panel — proceed as follows:

a. Crimp dual-hole compression lugs onto suitable

copper wires (#6 to #1 AWG) for

BATT

and

RTN

terminals, Feeds A and B.

b. Remove the black plastic terminal covers,

if installed.

c. Use a coarse, nonmetallic cleaning pad to clean

terminals and studs.

d. Lightly coat antioxidant on lugs and input

BATTERY

and

RETURN

terminals, and then

connect lugs to Feed A and B input terminals

on the back of the panel using the M5 KEPs

nuts and washers provided, shown in Figure 5.

Tighten the lugs to 20 in.-lb (2.25 N

•

m), max.

e. Re-install the terminal covers.

8. Make sure power is off (open breaker, dummy fuse or open fuse holder at the power distribution unit,

or PDU, before connecting this panel’s cables to the PDU.

Torque nuts to 20 in.-lb (2.25 N•m)

Anti-oxidant

compound

Figure 4 – Ground

Lug Connection

Heat shrink

tubing

Figure 5 – Compression Lug Inputs