102

HELIX™

Manual (P/N 26291)

Chapter 6: Recharge

Rev A (February 2018)

HELIX™

PCU Fire Suppression System

6.2.7 Actuator Removal & Cleaning

For systems using a Pneumatic Actuation Network with an Electric Nitrogen Actuator (P/N 20775

-

R)

the actuator must be removed, disassembled, cleaned, and reassembled after each use.

Actuator Removal (See Section 4.5):

1.

Locate Electric Nitrogen Actuator and Nitrogen Cylinder on Indoor Nitrogen Bracket.

2.

Slowly remove Nitrogen Cylinder (P/N 09956

-

R) from actuator, allowing any residual pressure

to escape. See Section 6.2.9 for Nitrogen Cylinder recharge instructions.

3.

Disconnect the Pneumatic Actuation Network from the nitrogen outlet port.

4.

Remove the actuator from the Bracket Back by removing the (2) Mounting Screws (P/N 10573)

using a 3/16” [5 mm] hex head wrench.

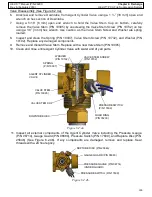

Actuator Disassembly (See Figure 6.2.7):

5.

Remove spent Linear Actuator (P/N 20500

-

R). Locate and discard the small stainless steel

disc which was displaced from the end of the Linear Actuator upon actuation. It is normally

found on top of the Puncture Stem Assembly.

6.

Using an 1 1/8” [29 mm] wrench, remove the Adapter (P/N 20458) with O

-

ring (P/N 10513)

from the top of the Actuator Body (P/N 20774).

7.

Remove the Puncture Stem Assembly (P/N 22873) with O

-

ring (P/N 09989) and (2) back

-

up

Rings (P/N 09993) from the Actuator Body (P/N 20774). Remove Spring (P/N 10097) and

Gasket (P/N 07247).

Actuator Cleaning (See Figure 6.2.7):

8.

Inspect and clean the inner bore of Actuator Body (P/N 20774). If any scarring or damage has

occurred to inner bore, replace the Actuator Body.

9.

Inspect and clean the Puncture Stem Assembly (P/N 22873). Replace the O

-

ring (P/N 09989)

and (2) back

-

up rings (P/N 09993) with new rings. These are included in the Actuator Rebuild

Kit (P/N 10939). Lubricate O

-

rings with Visilox (P/N L0172) or equivalent silicone style

lubricant .

10.

Inspect and clean the Adapter (P/N 20458). Replace O

-

ring (P/N 10513) with a new one. This

is also included in the Actuator Rebuild Kit (P/N 10939). Inspect and clean the Gasket (P/N

07247). Replace any damaged components.

Actuator Reassembly (See Figure 6.2.7):

11.

Insert Spring (P/N 10097), then Puncture Stem Assembly (P/N 22873) into Actuator Body (P/N

20774). Install the Adapter (P/N 20458) with O

-

ring (P/N 10513) and torque to 50 ft

-

lbs.

Function test the assembly using a Philips head screw driver inserted through the Linear

Actuator port in the Adapter to verify it works properly.

12.

Install the Gasket (P/N 07247).