EPC-250 IOI 6-18 All rights reserved © ALTRONIC, LLC 2018

16

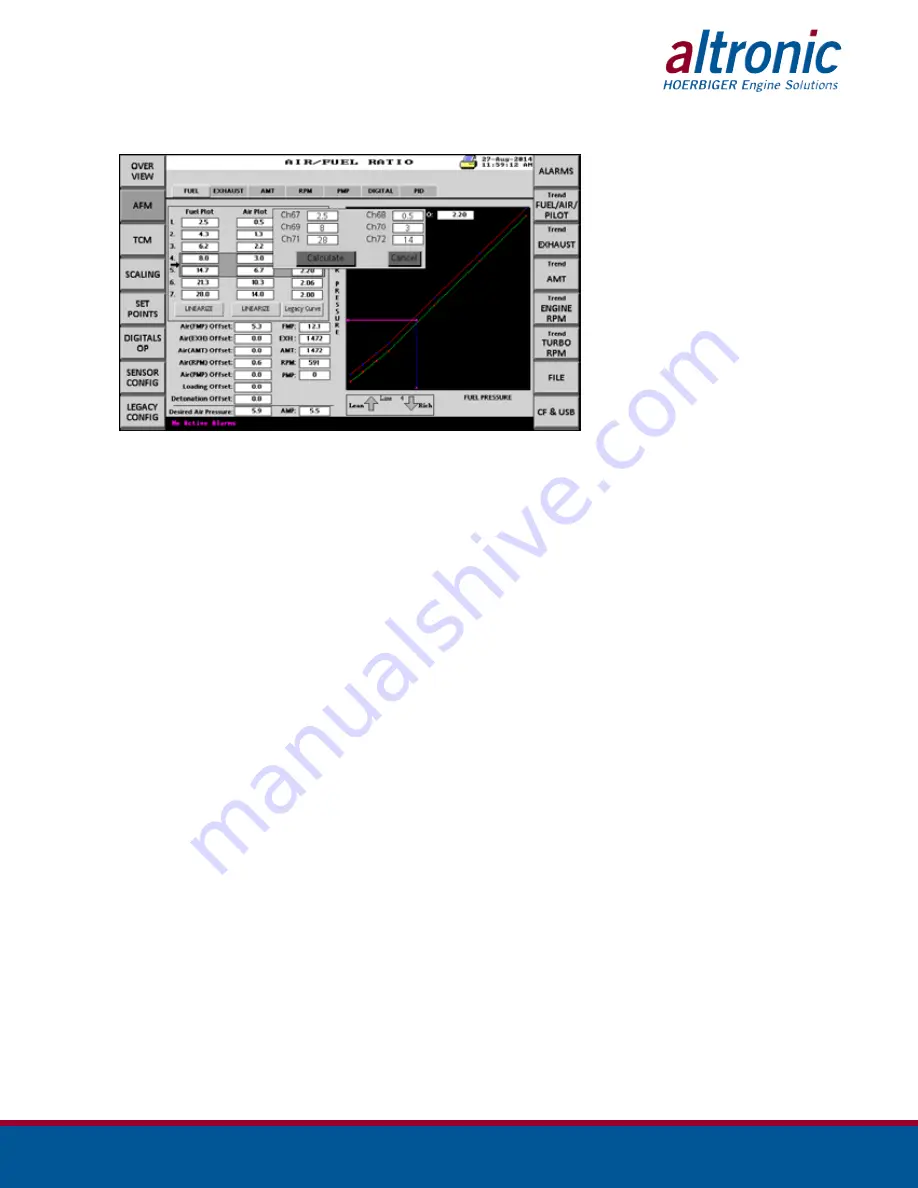

(first and seventh). Seven individual control offsets can be programmed. The

desired air pressure is the sum of all offsets.

9.2

Fuel plot

These values are obtained from the engine manufacturer or from an existing

EPC-200 configuration for the specific engine (air/fuel ratio curve). They must

be entered in ascending order from 1 to 7 (minimum to maximum) to obtain

a positive slope (y=mx+b). The fuel values represent the x coordinates of the

line equation. During operation the program calculates the line segment at

that instant which is indicated by the gray boxed area with an indicating arrow

using the four points of the gray box. This indicator changes as fuel pressure

increases or decreases. This helps the operator know which segment the EPC-

250 is using to calculate the air/fuel ratio in that instant. The calculated value

(desired air manifold pressure) of the 4-point line segment is compared to

the actual air manifold pressure. The difference between the two values is the

input to the PID calculations.

9.3

Air plot

These values are obtained from the engine manufacturer or from the EPC-200 for

the specific engine (air/fuel ratio curve). This value represents the Y value of the

line coordinate. It represents the input value of channel 3 (air manifold pressure).

9.4

Ratio

To enter a specific air/fuel ratio, press the corresponding data box to calculate

the air data point. This value corresponds to the fuel manifold pressure divided

by the air manifold pressure.

9.5

Offset

Each page represents an offset that can be used to manipulate the base air/fuel

offset. The fuel offset is the main parameter for control of the air/fuel ratio. The

desired air pressure is the sum of all offsets.