35

Inspections and maintenance

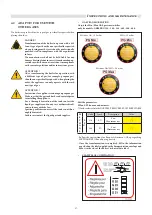

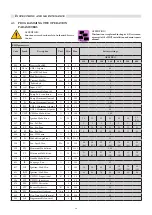

ANNUAL ROUTINE CHECKS

COMPONENT:

CHECK:

CONTROL METHOD/

INTERVENTION:

VG

(Gas valve ( 3 )

Does the valve modulate correctly?

Th

e check is carried out in “Calibration” mode,

requesting 100%, in 50%, the minimum mod-

ulation percentage.

Check that th

e fl

ame modulates.

S

M (flo

w sensor) ( 11 )

Do the sensors maintain their original fea-

tures?

12571 ohm at 20° C / 1762 ohm at 70° C.

Measurement to be carried out with the wires

disconnected (see Res/Temp table)

.

E ACC (ignition electrode ( 28 )

Th

e sparks generated before being secured is

less than 3 secs?

Disconnect the wire from the ionization elec-

trode and check the time required to make it safe.

TL (Overheating limit thermostat) ( 10 ) (51) Does the TL make the boiler safe in case of

overheating?

Heat the TL until it intervenes at 102°C and

check that it intervenes at 102°.

Condensate drain trap (27)

Was the drain trap deposited at the bottom? Clean the drain trap with water.

Heat exchanger body

If SL makes the boiler safe in case of an increase

in the level of condensate

If PF makes the boiler safe in case of a clogged

fl

ue exhaust

Check/remove any deposits from the com-

bustion chamber using a vacuum cleaner.

Then wash the heat exchanger body with

water and check correct draining from the

fl

ue

chamber and drain trap / remove any

fl

ue side

obstructions.

Burner ( 5 )

Make sure the burner’s mesh is clean

Remove any deposits using compressed air

blown from the mesh side

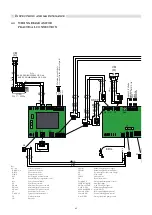

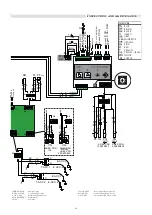

( Num ) = see key Par. 2.1

•

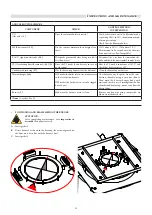

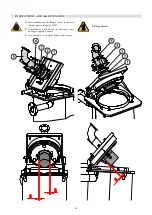

POSITIONING AND REASSEMBLING THE BURNER

ATTENTION:

After completing maintenance, it is imperative to

assemble the burner correctly.

A - Insert gasket 1

B - Direct burner 2 as shown in the drawing (the arrow engraved on

the door must be in line with the burner’

s fin

s).

C - Insert gasket 3

Содержание ARES Pro 150

Страница 2: ......

Страница 43: ...43 Inspections and maintenance ...