38

Inspections and maintenance

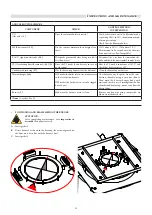

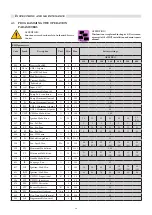

BMM parameters

Code

Symb.

Description

Unit Min. Max.

Factory settings

ARES PRO

150

230

300

348

400

500

600

803

Srv

Services Enabled

0

1

1

48

ChSet CH#1: Setpoint

°C

20

85

80

784

BC

Local BUS address

0

7

0

816

MI

ModBus Address

1

127

1

817

MT

Timeout Modbus

sec.

0

240

30

896

TU

°Fahrenheit

0

1

0

799

AC

Input 0/10V

0

2

0

376

DI1

Programmable Input #1

0

3

0

322

Po

Pump Post-circulation

min.

1

30

3

341

PL

Pump Minimum Control

%

0

100

30

313

Pr

Pump Maximum Control

%

0

100

100

31

HL

CH#1: Minimum Setpoint

°C

20

85

30

39

HH

CH#1: Maximum Setpoint

°C

20

85

85

792

CHP

CH: Max Modulation

%

0

100

100

619

IG

Ignition Modulation

%

30

80

50

35

45

45

45

40

35

(33)

527

PU

Fan: Pul./Rev

0

3

2

2

3

3

3

3

3

486

FP

Fan: Reg. Prop.

0

50

30

30

25

25

25

25

25

487

FI

Fan: Reg. Int.

0

50

9

9

25

25

25

25

25

489

Fpl

Fan: PWM min.

%

5

15

8

337

Fr

Modulation gradient

%

1.0

100.0

1.5

526

FU

Fan: Speed Max.

Hz

50

120

99

(94)

86

(82)

83

(81)

67

(64)

76

(69)

88

(83)

88

(92)

319

FH

Maximum Modulation

%

1.0

100.0

100

346

FL

Minimum Modulation

%

1.0

100.0

31

(31)

32

(32)

32

(32)

34

(34)

32

(36)

32

(33)

29

(30)

314

Sb

Standby Modulation

%

0

100

0

620

IP

Postpurge: Fan

%

0

100

65

617

IGL

Ignition: Mod. Min.

%

0

100

30

30

30

30

30

(36)

30

(34)

30

(29)

618

IGH

Ignition: Mod. Max.

%

0

100

80

80

74

54

54

45

40

353

HP

CH PID: Proportional

°K

0

50

25

354

HI

CH PID: Integrative

0

50

12

478

Hd

CH PID: Derivative

0

50

0

34

HY

Burner Hysteresis

°K

5.0

20.0

5.0

336

HS

Temperature Gradient

°C/min

0

30

5

483

rP

Gen: Temp. M

ax Diff

erential

°C

0.0

50.0

0.0

380

Al1

Programmable Sensor #1

0

2

0

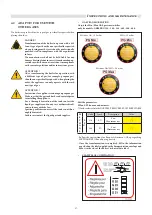

4.3 PROGRAMMING THE OPERATION

PARAMETERS

ATTENTION!

Function reserved exclusively to Authorised Service

Centres.

ATTENTION!

This

function is explained in chapter 8 (Device man-

agement) of the HSCP installation and maintenance

manual.

Содержание ARES Pro 150

Страница 2: ......

Страница 43: ...43 Inspections and maintenance ...