22

Instructions for the installer

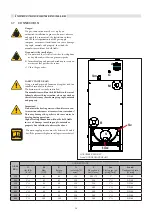

3.8 SYSTEM FILLING

AND EMPTYING

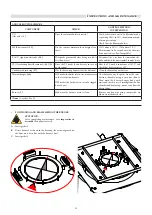

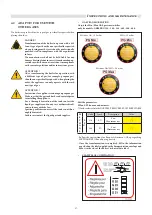

3.9 ELECTRICAL CONNECTIONS

General recommendations

Electrical safety of the appliance is only ensured when it is correctly

connected to an

efficien

t earthing system as spe

cifie

d by current safety

standards: earthing outlets, gas, water and central heating system pipes

are absolutely not suitable.

It is necessary to check this fundamental safety requirement; In case

of doubt, have an accurate inspection of the electrical system carried

out by professionally qua

lifie

d personnel, as the manufacturer is not

responsible for any damage caused by the lack of a earthing connection

in the system.

Have professionally qua

lifie

d personnel make sure the electrical system

is suitable for the maximum power absorbed by the appliance, as stated

on the plate, making sure in particular that the section of the system's

cables is suitable for the power absorbed by the appliance.

For the main power supply to the appliance, never use adapters, multiple

sockets and/or extension leads.

Th

e use of components involving use of electrical power requires some

fundamental rules to be observed such as:

- do not touch the appliance with wet and/or moist parts of the body

and/or barefoot;

- do not pull the electric cables;

- the appliance may not be used by children or unskilled individuals.

Danger! Before setting up the connections or any

operation on the electrical parts, always cut-o

ff

the

electrical supply and make sure it cannot be acciden-

tally re-connected.

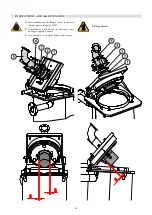

Remove the indicated screws in order to access the

panel.

Note:

Th

e image shown in the following page refers to

ARES PRO 150. For all other models, the HSCP heat

adjuster is in line with BCM.

When all system connections have been completed, the

circuit can b

e fi

lled.

To

fi

ll the system, you must provide a

fi

lling valve on

the system's return.

ATTENTI

ON!

Do not mix the heating water with antifreeze or anti-

corrosion substances at incorrect concentrations!

This

may damage gaskets and cause noise to develop

during operation.

Alpha will not be held liable in case of damage

caused to people, animals or property due to failure

to observe the above.

Once all of the system connections have been made, it is possible to

fill the circuit.

To fill the system install a

temporary

filling loop and

pressurisation unit to the system return pipe, in conjunction with

a correctly sized expansion vessel/s. Never use a pressurisation

unit to fill the system.

The boiler is fitted with a drain point, as shown in Section 2.

1

This

must never be used to drain the complete system, as dirt contained

in the system may accumulate in the boiler, preventing smooth

operation. Accordingly, the system must be equipped with its own

drain point/s.

Содержание ARES Pro 150

Страница 2: ......

Страница 43: ...43 Inspections and maintenance ...