W 3 2 S E R I E S

H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R

©ALKIN COMPRESSORS

24

To protect the system against an unexpected pressure rise due to a malfunctioning valve or component, safety

valves are installed after each stage and the final stage. These safety valves must be inspected periodically to insure

proper operation and pressure setting verification.

W32 series compressors have valves on all stages. They are designed to have an unobstructed passage of air with no

pressure loss; they are easy to maintain and replace.

Particular attention

must be paid to maintenance of the valves

as these valves are one of the most critical parts for proper operation of the compressor.

Do not

use oils other than

the recommended oils in this manuel for keeping the valves clean and free of carbon collecion. Inappropriate oils

may cause carbonization which will occur on the valve discs and springs, resulting in improper sealing of valves.

This will increase the operating temperatures which will cause the oil to deterioarite in a shorter time and effect the

operation of the valves negatively.

1.5 Lubrication System

Lubrication is performed by an oil pump. Oil pump takes the oil in the

crankcase, lubricates the 2nd and 3rd stage after enabling the oil pass through

oil filter and regulating valve. Pressure rise arises inside the regulating valve. It

reads on the oil pressure gauge on all W32 Series and controlled by oil

pressure switch on all W32 Electric Mariner and W32 Canopy models. Oil

Pressure Switch lets the electric motor and compressor stop when the oil

pressure goes under 4 Bar against any possible damages may arise due to lack

of lubrication. For W32 Petrol Engine Driven Mariner models which has

only oil pressure gauge but no oil pressure switch, oil pressure should be

controlled visually by the operator from the oil pressure gauge and the unit

should be immediately stopped manually when the pressure reads lower than

4 Bar.

Important!

Oil pump will work and enable lubrication in correct sense of rotation, only. Please make

sure of the compressor rotation direction. Otherwise, no oil pressure will be built up and the

compressor block will be seriosly damaged.

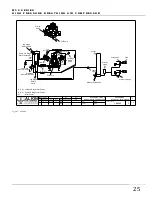

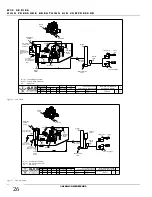

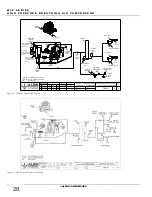

1.6 P&I Process and Instrumentation Diagram

The following process and instrument diagrams are prepared according to the physical appearance of the parts and

equipments rather than pneumatic symbols, in order to facilitate the better

understanding of the system by the users

who are not specifically trained to understand pneumatic symbols.

This compressor is designed to operate at a “single pressure” or “dual pressure”. This is, when the compressed air is

used to fill all the cylinders to that single pressure or dual pressure.

You can have the necessary information about the general layout of the system and operation process from the

process and instrument diagrams.

1.Oil Pump

2.Oil Filter

3.Oil Regulating Valve

4.Guide Piston

5.Oil

Содержание W32 Canopy

Страница 1: ...W32 SERIES...

Страница 3: ...InstructionsManual and Parts List...

Страница 4: ......

Страница 10: ...W 3 2 S E R I E S H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R ALKIN COMPRESSORS 10...

Страница 46: ...W 3 2 S E R I E S H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R ALKIN COMPRESSORS 46...

Страница 60: ...W 3 2 S E R I E S H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R ALKIN COMPRESSORS 60...

Страница 66: ...W 3 2 S E R I E S H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R ALKIN COMPRESSORS 66...

Страница 88: ...W 3 2 S E R I E S H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R ALKIN COMPRESSORS 88...

Страница 94: ...W 3 2 S E R I E S H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R ALKIN COMPRESSORS 94...

Страница 100: ...W 3 2 S E R I E S H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R ALKIN COMPRESSORS 100...

Страница 106: ...W 3 2 S E R I E S H I G H P R E S S U R E B R E A T H I N G A I R C O M P R E S S O R ALKIN COMPRESSORS 106...