43

To initiate the component test sequence, shut OFF the room thermostat or disconnect the "R"

thermostat lead. Briefly short the TEST/TWIN terminal to the "Com 24V" terminal. Status LED

will flash code and then turn ON the inducer motor. The inducer motor will run for the entire

component test. The hot surface ignitor, blower motor fan speed (on AMBER LED boards

only) blower motor-heat speed, and blower motor-cool speed will be turned ON for 10-15

seconds each. Gas Valve and Humidifier will not be turned on.

CONTINUOUS OFF

- Check for 115VAC at L1 and L2, and 24VAC at SEC-1 and SEC-2.

CONTINUOUS ON

- Control has 24VAC power.

RAPID FLASHING

- Line voltage (115VAC) polarity reversed. If twinned, refer to twinning kit instructions.

LED CODE

STATUS

11 NO PREVIOUS CODE

- Stored status code is erased automatically after 72 hours. On

RED LED boards stored status codes can also be erased when power

(115 VAC or 24 VAC) to control is interrupted.

12 BLOWER ON AFTER POWER UP

(115 VAC or 24 VAC) -Blower runs for 90 seconds,

if unit is powered up during a call for heat (R-W closed) or R-W opens during blower

on-delay.

13 LIMIT CIRCUIT LOCKOUT

- Lockout occurs if the limit, draft safeguard, flame rollout, or

blocked vent switch (if used) is open longer than 3 minutes.

- Control will auto reset after three hours. - Refer to #33.

14 IGNITION LOCKOUT -

Control will auto-reset after three hours. Refer to #34.

21 GAS HEATING LOCKOUT

- Control will NOT auto reset.

Check for: - Mis-wired gas valve

-Defective control (valve relay)

22 ABNORMAL FLAME-PROVING SIGNAL

- Flame is proved while gas valve is de-

energized. Inducer will run until fault is cleared. Check for: - Leaky gas valve

- Stuck-open gas valve

23 PRESSURE SWITCH DID NOT OPEN

Check for:

- Obstructed pressure tubing. - Pressure switch stuck closed.

24 SECONDARY VOLTAGE FUSE IS OPEN

Check for:

- Short circuit in secondary voltage (24VAC) wiring.

If status code recall is needed, briefly remove then reconnect one main limit wire to display stored status code. On RED LED boards do not remove power or blower door before initiating status code recall. After

status code recall is completed component test will occur.

327596-101 REV. B

31

PRESSURE SWITCH DID NOT CLOSE OR REOPENED

- If open longer than five minutes,

inducer shuts off for 15 minutes before retry. Check for: - Excessive wind

- Proper vent sizing - Defective inducer motor

- Low inducer voltage (115VAC) - Defective pressure switch

- Inadequate combustion air supply - Disconnected or obstructed pressure tubing

- Low inlet gas pressure (if LGPS used) - Restricted vent

If it opens during blower on-delay period, blower will come on for the selected blower

off-delay.

33 LIMIT CIRCUIT FAULT -

Indicates a limit, draft safeguard, flame rollout, or blocked vent

switch (if used) is open. Blower will run for 4 minutes or until open switch remakes

whichever is longer. If open longer than 3 minutes, code changes to lockout #13.

If open less than 3 minutes status code #33 continues to flash until blower shuts off.

Flame rollout switch and BVSS require manual reset. Check for: - Restricted vent

- Proper vent sizing - Loose blower wheel. - Excessive wind

- Dirty filter or restricted duct system.

- Defective blower motor or capacitor. - Defective switch or connections.

- Inadequate combustion air supply (Flame Roll-out Switch open).

34 IGNITION PROVING FAILURE

- Control will try three more times before lockout #14

occurs. If flame signal lost during blower on-delay period, blower will come on for the

selected blower off-delay. Check for: - Flame sensor must not be grounded

- Oxide buildup on flame sensor (clean with fine steel wool).

- Proper flame sense microamps (.5 microamps D.C. min., 4.0 - 6.0 nominal).

- Gas valve defective or gas valve turned off - Manual valve shut-off

- Defective Hot Surface Ignitor - Control ground continuity

- Low inlet gas pressure - Inadequate flame carryover or rough ignition

- Green/Yellow wire

MUST

be connected to furnace sheet metal

45 CONTROL CIRCUITRY LOCKOUT

Auto-reset after one hour lockout due to;

- Gas valve relay stuck open - Flame sense circuit failure - Software check error

Reset power to clear lockout. Replace control if status code repeats.

SERVICE

COMPONENT TEST

EACH OF THE FOLLOWING STATUS CODES IS A TWO DIGIT NUMBER WITH THE FIRST DIGIT DETERMINED BY THE NUMBER OF SHORT FLASHES AND THE SECOND DIGIT BY THE NUMBER OF LONG FLASHES.

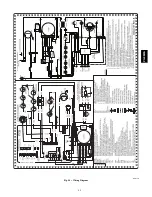

A04223

Fig. 50 -- Service Label

CARE AND MAINTENANCE

FIRE OR EXPLOSION HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Never store anything on, near, or in contact with the

furnace, such as:

1. Spray or aerosol cans, rags, brooms, dust mops,

vacuum cleaners, or other cleaning tools.

2. Soap powders, bleaches, waxes or other cleaning

compounds, plastic or plastic containers, gasoline,

kerosene, cigarette lighter fluid, dry cleaning fluids,

or other volatile fluids.

3. Paint thinners and other painting compounds, paper

bags, or other paper products.

!

WARNING

For continuing high performance and to minimize possible

equipment failure, periodic maintenance must be performed on

this equipment. Consult your local dealer about proper frequency

of maintenance and the availability of a maintenance contract.

ELECTRICAL SHOCK AND FIRE HAZARD

Failure to follow this warning could result in personal

injury, death or property damage.

Turn off the gas and electrical supplies to the unit and

install lockout tag before performing any maintenance

or service. Follow the operating instructions on the label

attached to the furnace.

!

WARNING

CARBON MONOXIDE POISONING AND

FIRE HAZARD

Failure to follow this warning could result in personal

injury, death and/or property damage.

Never operate unit without a filter or with filter access door

removed.

!

WARNING

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care

and wear appropriate protective clothing, safety glasses and

gloves when handling parts and servicing furnaces.

CAUTION

!

The minimum maintenance on this furnace is as follows:

1. Check and clean/replace air filter each month or more fre-

quently if required. Replace if torn.

2. Check blower motor and wheel for cleanliness each heat-

ing and cooling season. Clean as necessary.

3. Check electrical connections for tightness and controls for

proper operation each heating season. Service as neces-

sary.

4. Inspect burner compartment before each heating season

for rust, corrosion, soot or excessive dust. If necessary,

have furnace and burner serviced by a qualified service

agency.

5. Inspect the vent pipe/vent system before each heating sea-

son for rust, corrosion, water leakage, sagging pipes or

broken fittings. Have vent pipes/vent system serviced by a

qualified service agency.

PG

8M

EA

Содержание PG8JEA

Страница 4: ...4 A10269 Fig 2 Clearances to Combustibles PG8MEA ...

Страница 28: ...28 A10133 Fig 33 Chimney Inspection Chart PG8MEA ...

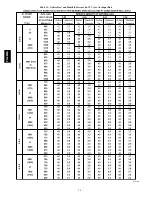

Страница 38: ...38 Table 13 Orifice Size and Manifold Pressure In W C for Gas Input Rate A10180 PG8MEA ...

Страница 39: ...39 Table 13 Orifice Size and Manifold Pressure In W C for Gas Input Rate CONT A10180A PG8MEA ...

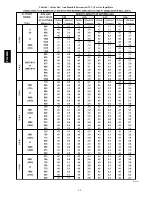

Страница 40: ...40 Table 14 Orifice Size And Manifold Pressure In W C For Gas Input Rate A10181 PG8MEA ...

Страница 41: ...41 Table 14 Orifice Size And Manifold Pressure In W C For Gas Input Rate CONT A10181A PG8MEA ...

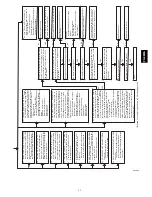

Страница 49: ...49 A08176 Fig 54 Wiring Diagram PG8MEA ...