14

Upflow and Horizontal Furnaces

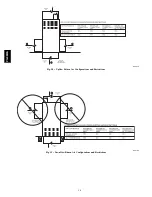

Connect supply--air duct to flanges on furnace supply--air outlet.

Bend flange upward to 90

_

with wide duct pliers. (See Fig. 14.)

The supply--air duct must be connected to ONLY the furnace

supply--outlet--air duct flanges or air conditioning coil casing

(when used). DO NOT cut main furnace casing side to attach

supply air duct, humidifier, or other accessories. All accessories

MUST be connected to duct external to furnace main casing.

NOTE

: For horizontal applications, the top--most flange may be

bent past 90 degrees to allow the evaporator coil to hang on the

flange temporarily while the remaining attachment and sealing of

the coil are performed.

Downflow Furnaces

Connect supply--air duct to supply--air outlet on furnace. Bend

flange inward past 90

_

with wide duct pliers. (See Fig. 14.) The

supply--air duct must be connected to ONLY the furnace supply

outlet or air conditioning coil casing (when used). When installed

on combustible material, supply--air duct must be connected to

ONLY the factory--approved accessory subbase or a factory--

approved air conditioning coil casing. DO NOT cut main furnace

casing to attach supply side air duct, humidifier, or other

accessories. All accessories MUST be connected to duct external

to furnace casing.

UPFLOW

DOWNFLOW

HORIZONTAL

YES

NO

NO

YES

YES

YES

NO

120

°

MIN

YES

120

°

MIN

YES

120

°

MIN

90

°

90

°

A02020

Fig. 14 -- Duct Flanges

1

/

4

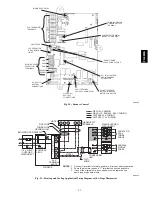

" (6mm) THREADED ROD

4 REQ.

SECURE ANGLE

IRON TO BOTTOM

OF FURNACE WITH

3 #8 x

3

/

4

" (19mm) SCREWS

TYPICAL FOR 2 SUPPORTS

1” (25mm) SQUARE, 1-1/4”x1-1/4”x1/8” (32x32x3mm)

ANGLE IRON OR UNI-STRUT MAY BE USED

(2) HEX NUTS, (2) WASHERS & (2) LOCK WASHERS

REQ. PER ROD

8" (203mm)

MIN

FOR DOOR REMOVAL

OUTER DOOR

A S SEMBLY

A10130

Fig. 15 -- Horizontal Unit Suspension

PG

8M

EA

Содержание PG8JEA

Страница 4: ...4 A10269 Fig 2 Clearances to Combustibles PG8MEA ...

Страница 28: ...28 A10133 Fig 33 Chimney Inspection Chart PG8MEA ...

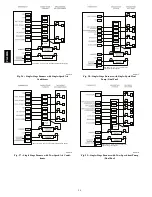

Страница 38: ...38 Table 13 Orifice Size and Manifold Pressure In W C for Gas Input Rate A10180 PG8MEA ...

Страница 39: ...39 Table 13 Orifice Size and Manifold Pressure In W C for Gas Input Rate CONT A10180A PG8MEA ...

Страница 40: ...40 Table 14 Orifice Size And Manifold Pressure In W C For Gas Input Rate A10181 PG8MEA ...

Страница 41: ...41 Table 14 Orifice Size And Manifold Pressure In W C For Gas Input Rate CONT A10181A PG8MEA ...

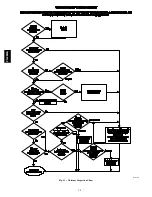

Страница 49: ...49 A08176 Fig 54 Wiring Diagram PG8MEA ...