50

Is LED status light on?

Is LED status light b

linking rapidly without a

pause?

Is LED status light b

linking ON/OFF slo

w

ly

with a combination of shor

t and long

flashes?

Deter

m

ine status code

.

The status code is

a

2 digit number with the first digit deter

m

ined

by

t

h

e

number of

shor

t

flashes

and

the

second

digit b

y

the number of long flashes?

Go to section belo

w f

o

r the status code that

w

a

s flashed.

Is there 115V at L1 and L2?

Is there 24V at SEC-1 and SEC-2?

Replace fur

nace control.

Chec

k f

o

r correct line v

o

ltage polarity

. If units

are twinned, chec

k f

o

r proper lo

w-v

oltage

(24V) transf

o

rm

er phasing.

To

recall status code briefly rem

o

v

e

and reconnect one RED wire from the draft

saf

e

guard s

witch to displa

y stored status code

. On RED LED control do not

remo

v

e

po

wer or b

lo

wer access panel bef

ore initiating status code recall.

Y

o

u

can also recall the pre

vious

status

code b

y

momentar

ily

shor

ting the

TEST/TWIN

ter

m

inal to Com24V ter

m

inal until the LED goes out.

LED will flash the status

code of the pre

v

ious f

ault or status code #11 (1 shor

t and 1 long flash) if there

w

a

s no pre

v

ious f

a

ult.

After the control repeats the code 4 times

, the control

will

go through a brief component test sequence

.

The

inducer will star

t and

ru

n

fo

r the entire component test.

The

HSI,

b

lo

w

er motor F

A

N speed (AMBER LE

D

boards only) HEA

T

speed, and COOL speed will r

u

n f

o

r 10 – 15 seconds each.

Gas v

alv

e and humidifier will not be tur

ned on.

W

a

s there a pre

v

ious status code

other than #11?

Is door s

w

itch closed?

Is there 115V going to s

w

itch?

Replace door s

w

itch.

Replace transf

or

mer

.

Does the control respond to

W

, Y1 (if present),

Y/Y2, and G (24V) ther

mostat signals?

Run system through

a heating or cooling cycle

to chec

k operation.

Status codes are erased

after 72 hours

. On RED LED boards stored

status codes can also be erased whene

v

er

(115V or 24V) is interr

u

pted.

Replace fur

n

ace control.

Is door s

w

itch closed?

Is circuit break

er closed?

Chec

k f

o

r continuity

in wire from circuit break

e

r

to fur

n

ace

.

Close circuit break

er and go bac

k to ST

AR

T

.

Chec

k room ther

mostat or

interconnecting cab

le

.

Is 24V present at

W

,

Y1 (if present),

Y/Y2 or

G ther

mostat ter

m

inals on the fur

n

ace control?

Disconnect all the ther

mostat wires from the

fur

n

ace control.

Does the prob

lem repeat when using

a jumper wire?

The ther

mostat is not compatib

le with the

fur

nace

control.

Either install a ballast resistor

,

connect the Com24V ther

mostat ter

m

inal to

the ther

mostat, or replace the ther

mostat.

NO

YES

YES

NO

NO

YES

YES

YES

YES

NO

YES

YES

NO

YES

NO

YES

NO

NO

NO

YES

NO

YES

NO

ST

AR

T

NO

A02106A

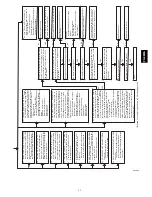

Fig. 55 -- Troubleshooting Guide

PG

8M

EA

Содержание PG8JEA

Страница 4: ...4 A10269 Fig 2 Clearances to Combustibles PG8MEA ...

Страница 28: ...28 A10133 Fig 33 Chimney Inspection Chart PG8MEA ...

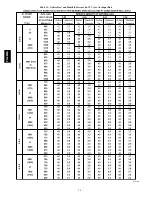

Страница 38: ...38 Table 13 Orifice Size and Manifold Pressure In W C for Gas Input Rate A10180 PG8MEA ...

Страница 39: ...39 Table 13 Orifice Size and Manifold Pressure In W C for Gas Input Rate CONT A10180A PG8MEA ...

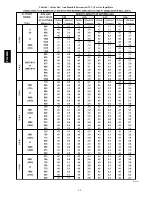

Страница 40: ...40 Table 14 Orifice Size And Manifold Pressure In W C For Gas Input Rate A10181 PG8MEA ...

Страница 41: ...41 Table 14 Orifice Size And Manifold Pressure In W C For Gas Input Rate CONT A10181A PG8MEA ...

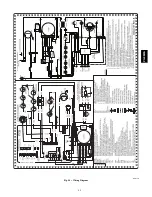

Страница 49: ...49 A08176 Fig 54 Wiring Diagram PG8MEA ...