35

c. Adjust air temperature rise by adjusting blower speed. In-

crease blower speed to reduce temperature rise. Decrease

blower speed to increase temperature rise

d. Turn thermostat down below room temperature and re-

move blower access door.

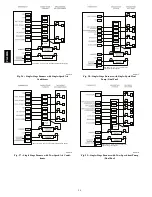

e. To change motor speed selection for heating, remove

blower motor lead from control HEAT terminal (See Fig.

24.) Select desired blower motor speed lead from one of

the other terminals and relocate it to the HEAT terminal

(See Table 11 for lead color identification). Reconnect

original lead to SPARE terminal.

f. Repeat steps a through e.

g. When correct input rate and temperature rise is achieved,

turn gas valve ON/OFF switch to OFF.

h. Remove manometer or similar device from gas valve.

i. Reinstall manifold pressure tap plug in gas valve.

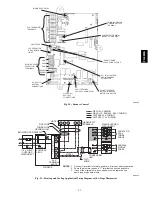

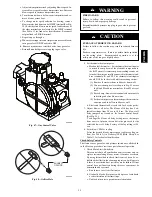

A06666

Fig. 47 -- Gas Control Valve

BURNER

ORIFICE

A93059

Fig. 48 -- Orifice Hole

FIRE HAZARD

Failure to follow this warning could result in personal

injury, death, and/or property damage.

Reinstall manifold pressure tap plug in gas valve to prevent

gas leak.

!

WARNING

FURNACE OVERHEATING HAZARD

Failure to follow this caution may result in reduced furnace

life.

Recheck temperature rise. It must be within limits specified

on the rating plate.

Recommended operation is at the

mid--point of rise range or slightly above.

CAUTION

!

6. Set thermostat heat anticipator.

a. Mechanical thermostat -- Set thermostat heat anticipator

to match the amp. draw of the electrical components in

the R--W circuit. Accurate amp. draw readings can be ob-

tained at the wires normally connected to thermostat sub-

base terminals, R and W. The thermostat anticipator

should NOT be in the circuit while measuring current.

(1.) Remove thermostat from subbase or from wall.

(2.) Connect an amp. meter as shown in Fig. 49 across

the R and W subbase terminals or R and W wires at

wall.

(3.) Record amp. draw across terminals when furnace is

in heating and after blower starts.

(4.) Set heat anticipator on thermostat per thermostat in-

structions and install on subbase or wall.

b. Electronic thermostat: Set cycle rate for 4 cycles per hr.

7. Adjust blower off delay The blower off delay has 4 ad-

justable settings from 90 sec to 180 sec. The blower off

delay jumpers are located on the furnace control board.

(See Fig. 24.)

To change the blower off delay setting, move the jumper

from one set of pins on the control to the pins used for the

selected blower off delay. Factory off delay setting is 120

sec.

8. Set airflow CFM for cooling

Select the desired blower motor speed lead for cooling air-

flow. See Table 5--Air Delivery--CFM (With Filter). See

Table 11 for lead color identification.

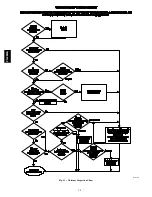

Check Safety Controls

The flame sensor, gas valve, and pressure switch were all checked

in the Start--up procedure section as part of normal operation.

1. Check Main Limit Switch(es)

This control shuts off combustion control system and en-

ergizes air--circulating blower motor, if furnace overheats.

By using this method to check limit control, it can be es-

tablished that limit is functioning properly and will operate

if there is a restricted duct system or motor failure. If limit

control does not function during this test, cause must be

determined and corrected.

a. Run furnace for at least 5 minutes.

b. Gradually block off return air with a piece of cardboard

or sheet metal until the limit trips.

c. Unblock return air to permit normal circulation.

PG

8M

EA

Содержание PG8JEA

Страница 4: ...4 A10269 Fig 2 Clearances to Combustibles PG8MEA ...

Страница 28: ...28 A10133 Fig 33 Chimney Inspection Chart PG8MEA ...

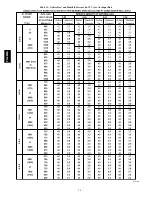

Страница 38: ...38 Table 13 Orifice Size and Manifold Pressure In W C for Gas Input Rate A10180 PG8MEA ...

Страница 39: ...39 Table 13 Orifice Size and Manifold Pressure In W C for Gas Input Rate CONT A10180A PG8MEA ...

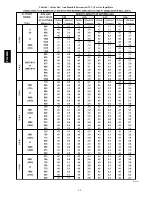

Страница 40: ...40 Table 14 Orifice Size And Manifold Pressure In W C For Gas Input Rate A10181 PG8MEA ...

Страница 41: ...41 Table 14 Orifice Size And Manifold Pressure In W C For Gas Input Rate CONT A10181A PG8MEA ...

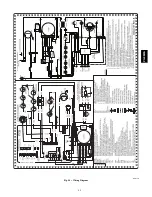

Страница 49: ...49 A08176 Fig 54 Wiring Diagram PG8MEA ...