Scratch Testing E

Agilent Nano Indenter G200 User’s Guide

E-17

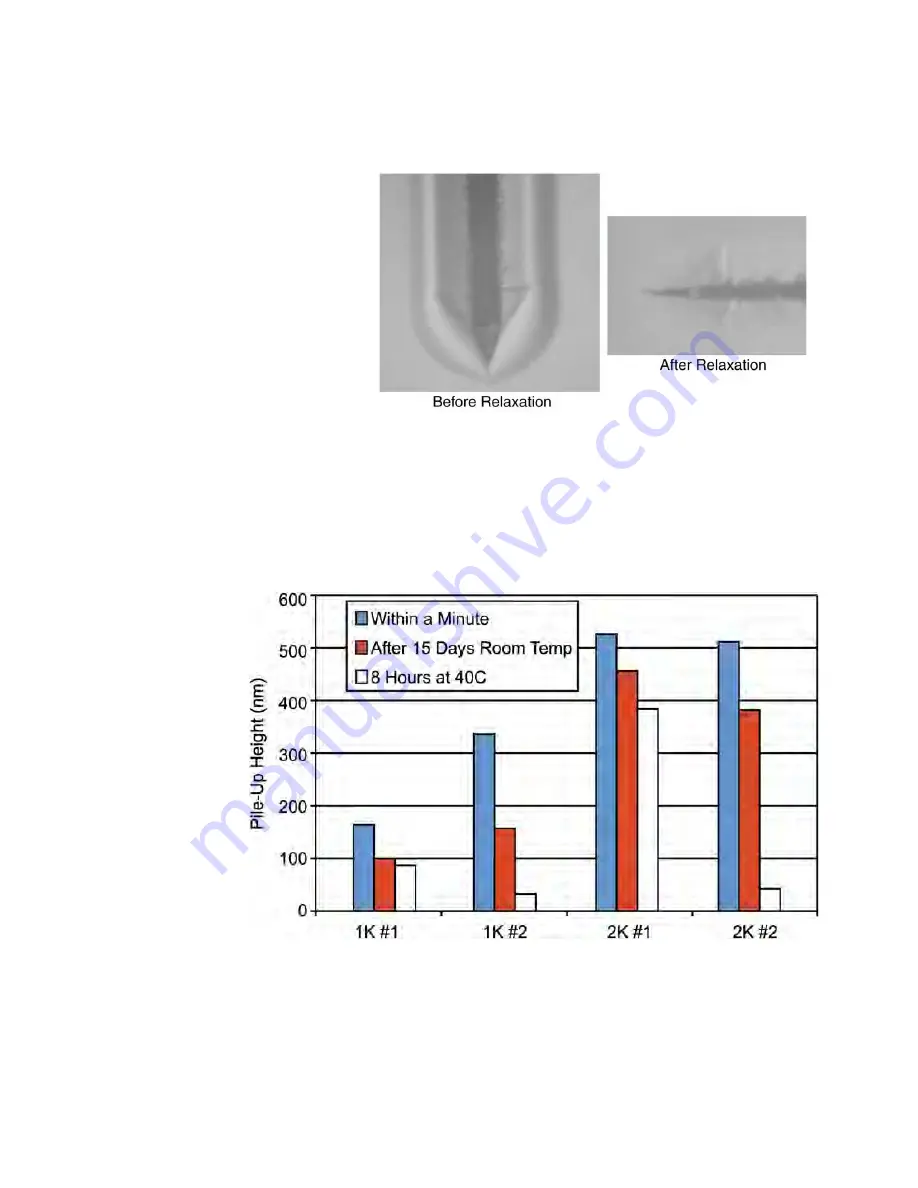

Figure E-14

Optical image of a scratch made with the edge of a cube

corner

shows the evolution of the pile-up height due to

visco-plastic relaxation after the scratch is made (for different systems

of automotive paints).

Figure E-15

Evolution of the Pile-Up Height due to visco-plastic

relaxation

Maintaining the same normal load, variation in scratch velocity results

in a variation of the scratch width. Faster motion results in a thinner

residual scratch, corresponding to a harder material.

Содержание Nano Indenter G200

Страница 1: ...Agilent Technologies Agilent Technologies Nano Indenter G200 User s Guide...

Страница 14: ...Agilent Nano Indenter G200 User s Guide 9 Express Test Tip Calibration H 12 Express Test Varied Force H 12...

Страница 96: ...NanoSuite 4 Agilent Nano Indenter G200 User s Guide 4 4 Export Menu Mode Menu System Menu Help Menu...

Страница 109: ...NanoSuite 4 Agilent Nano Indenter G200 User s Guide 4 17 Figure 4 18Load Review page configuration dialog box...

Страница 117: ...NanoSuite 4 Agilent Nano Indenter G200 User s Guide 4 25 Figure 4 27Real Time Graph Setup dialog box...

Страница 121: ...NanoSuite 4 Agilent Nano Indenter G200 User s Guide 4 29 Figure 4 31User Configuration dialog box...

Страница 136: ...NanoSuite 4 Agilent Nano Indenter G200 User s Guide 4 44 Exit Use this icon to exit the software...

Страница 263: ...Commonly Used Procedures 6 Agilent Nano Indenter G200 User s Guide 6 44 Figure 6 62Flowchart 1 Figure 6 63Flowchart 2...

Страница 478: ...Agilent Technologies Agilent Nano Indenter G200 User s Guide Part Number G2A 13192 1 Rev C Agilent Technologies Inc 2012...