22

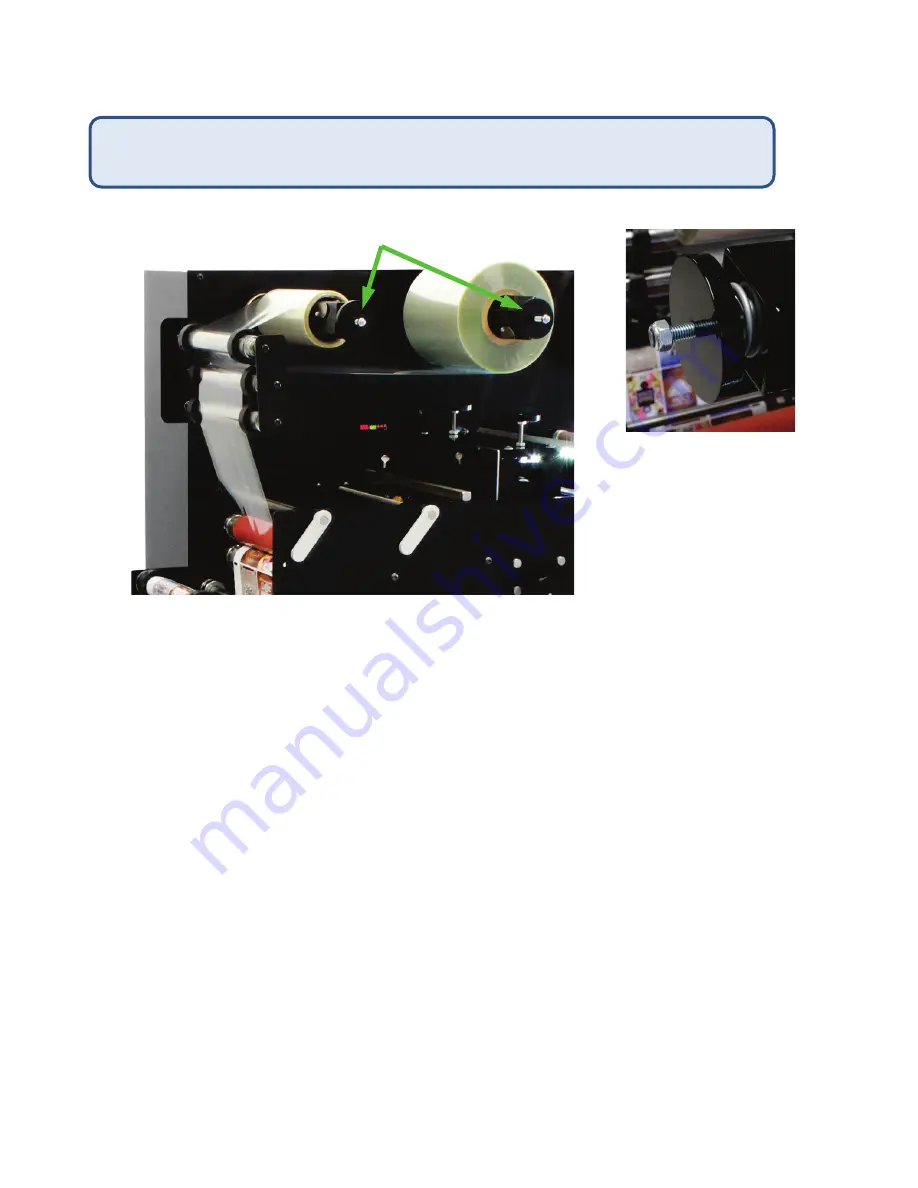

Laminate Adjustments

•

Do not over tighten your laminate unwind clutch adjustment. Excess tension can cause the web

to move and the labels to curl. There should be just enough tension to keep the laminate taut

as it unwinds.

•

Make sure that your laminate liner rewind has less tension than the laminate unwind. Excess

tension may cause the laminate to run loose and follow the liner.

•

Make sure the laminating rollers are adjusted down until they stop, using firm finger pressure

•

The paper clutch must be used. It should create a firm tension on the printed media between

the paper clutch and the laminating rollers. Without a good tension in this area the web may

drift from side to side.

•

Ensure that the paper guides are adjusted so that there is no room for the media to move from

side to side. Your printed media roll should be straight and tight, to help avoid any web

movement.

Tension adjustments are important when running lamination. Follow the instructions

below to ensure that your laminate and media webs run in line consistently.

Tension adjusters

•

Clockwise: more

tension, faster

rotation

•

Counter-clockwise:

less tension, slower

rotation