17

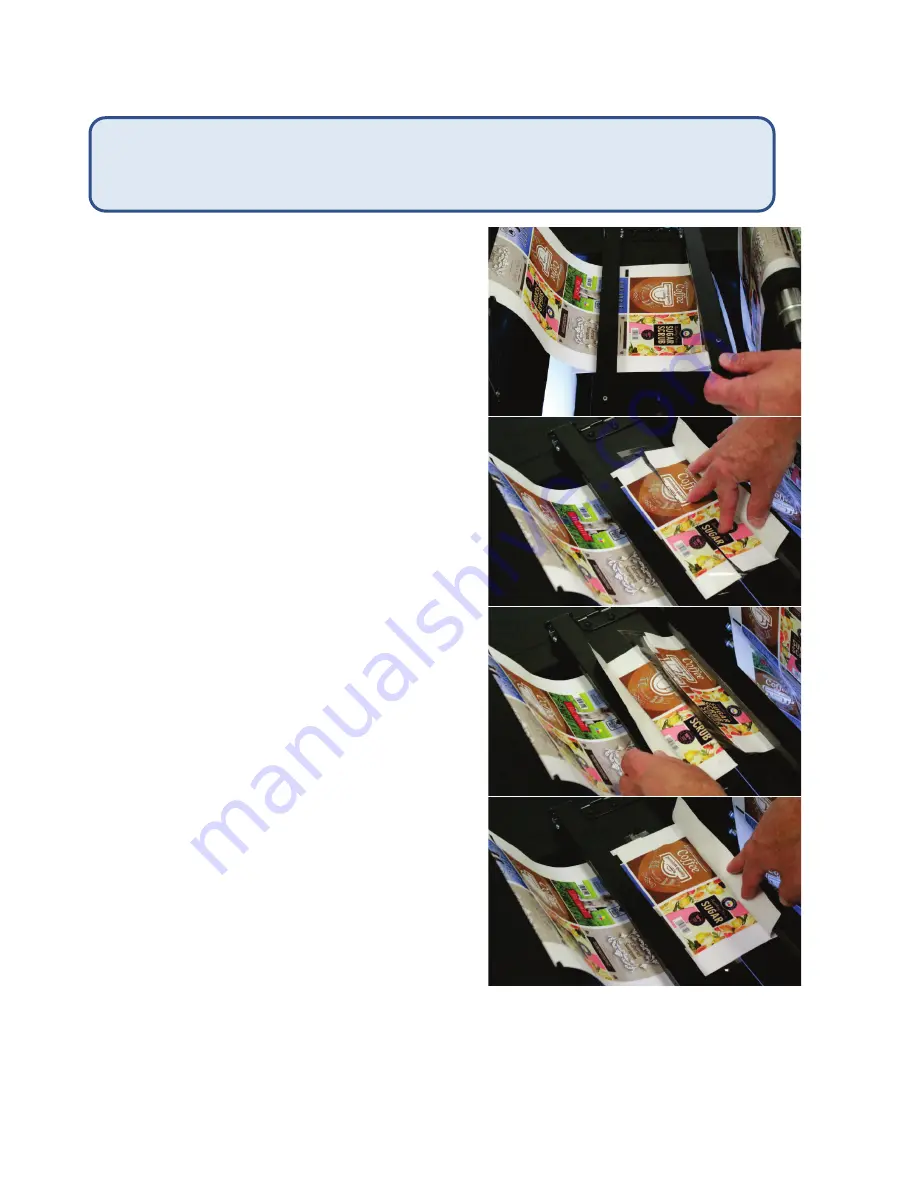

Using the splicing table

1.

When the current roll of media is finished,

stop the DLP-2100 or the loop sensor will stop

the machine when it sees no media.

2.

Push the Emergency Stop button.

3.

Load the new roll of media onto the unwind

mandrel, with the media unwinding clockwise.

4.

Load into the printer and print enough so the

new media can be held in place by both

locking arms.

5.

Align the old and new media on the splicing

table, with the new media on top of the old.

6.

Lower both left and right locking arms.

7.

Using a sharp knife, cut through both pieces of

media, in the slot on the splicing table.

8.

Lift

both

layers of media on

right side

and

apply tape under the bottom layer, as

smoothly as possible. Tape will be above left

side.

9.

Lift

top

layer of media on

left side

and apply

to the tape as well aligned and as smoothly as

possible.

10.

If laminate is not being applied, place another

piece of tape across the top of the splice; if

laminate is being applied, the top tape is not

required.

11.

Lift both locking arms and remove the two

sections of detached media.

12.

Using scissors or a sharp knife, cut the excess

tape on each side of the media, as close to the

media as possible.

a.

Do NOT wrap excess tape over the

edges of the media!

13.

Print enough length to allow the splicing table

to be lifted out of the media path.

14.

Release the Emergency stop button and

Restart

the DLP-2100. You are now ready to continue.

Note:

The printed images do not need to splice together perfectly, but you will need to perform a

Home Cycle

when the splice gets to the cutting cylinder.

The splicing table enables the user to join rolls of media together neatly and correctly, to

allow smooth passage through the die cutting, stripping, and slitting processes. Follow

the instructions below on the use of the DLP-2100 splicing table.

5 & 6

9

9

8