30

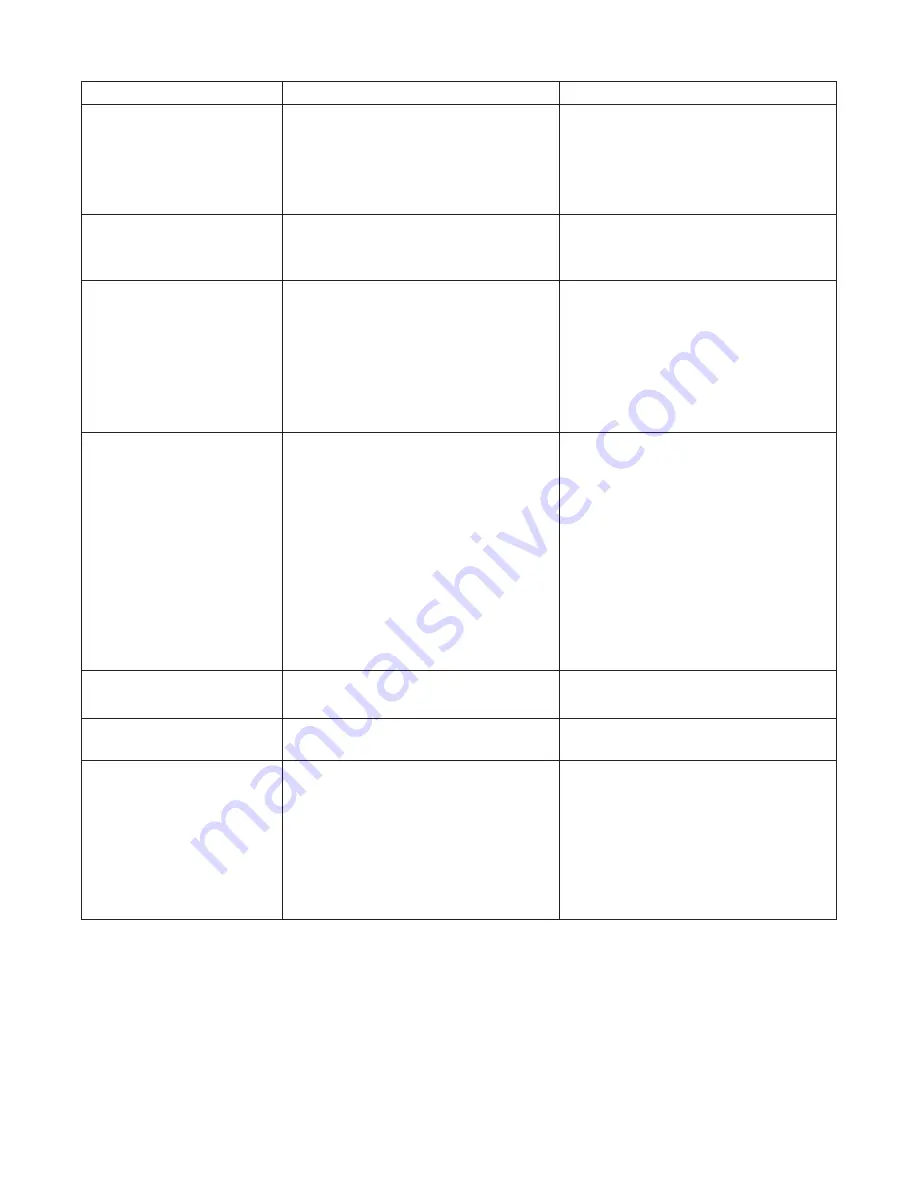

System Troubleshooting

Problem

Possible Cause

Solution

Brine tank overflow.

a. Uncontrolled refill flow rate.

b. Air leak in regenerant line to air check.

c. Drain control clogged with resin or other

debris.

a. Remove brine control to clean ball

and seat.

b. Check all connections in regenerant line

for leaks.

c. Clean drain control.

Flowing or dripping water at

drain or regenerant line after

regeneration.

a. Valve stem return spring weak.

b. Debris is preventing valve disc from

closing.

a. Replace spring. (Contact dealer)

b. Remove debris.

Hard water leakage after

regeneration.

a. Improper regeneration.

b. Leaking of external bypass valve.

c. O-Ring around riser pipe damaged.

d. System capacity too low due to incorrect

resin volume setting.

a. Repeat regeneration after making certain

correct regenerant dosage was set.

b. Replace bypass valve. (Contact dealer)

c. Replace O-ring.

d. Reset control and program resin volume to

correct setting.

Control will not draw brine.

a. Low water pressure.

b. Restricted drain line.

c. Injector plugged.

d. Injector defective.

e. Valve disc 2 and/or 3 not closed.

f. Air check valve prematurely closed.

a. Make correct setting according to

instructions.

b. Remove restriction.

c. Clean injector and screen.

d. Replace injector and cap. (Contact dealer)

e. Remove foreign matter from disc and

check disc for closing by pushing in on

stem. Replace if needed. (Contact dealer)

f. Put control momentarily into brine refill.

Replace or repair air check if needed.

(Contact dealer)

Control will not regenerate

automatically.

a. AC adapter or motor not connected.

b. Defective motor.

a. Connect power.

b. Replace motor. (Contact dealer)

Control regenerates at wrong

time of day.

a. Control set incorrectly.

a. Correct the time setting according to

instructions.

Valve will not draw brine.

a. Low water pressure.

b. Restricted drain line.

c. Injector plugged.

d. Injector defective.

e. Air check valve closes prematurely on

brine pickup tube.

a. Set pump to maintain 20 psi at softener.

b. Change drain to remove restriction.

c. Clean injector and screen.

d. Replace injector. (Contact dealer)

e. Put control momentarily into brine/slow

rinse. Replace or repair air check if needed.

(Contact dealer)

Содержание Origins WC300

Страница 1: ...Operation Manual 00947 1821 EA 03671...

Страница 33: ...Manuel d utilisation 00947 1821 EA 03671 A D O U C I S S E U R D E AU WC300...

Страница 66: ...66...

Страница 67: ...67...