l&M V 6584 R16 sec1

©ASCO Valve, Inc. 50 Hanover Road, Florham Park, New Jersey 07932

www.ascovalve.com

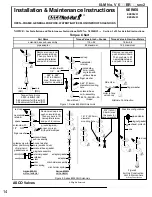

NOTE:

Connector housing may be rotated in 90° increments from

position shown for alternate positioning of cable entry.

Check DIN connector terminal block for electrical markings. Then

make electrical hookup to terminal block according to markings

on it. Snap terminal block into connector cover and install center

screw.

Position connector gasket on solenoid and install plug connector.

Torque center screw to 5±1 in-lbs [0,6±1,1 Nm].

6.

5.

NOTE:

Alternating current (AC) and direct current (DC) sole-

noids are built differently and cannot be converted from one to the

other by changing the coil.

Installation of Solenoid

Solenoids may be assembled as a complete unit. Tightening is

accomplished by means ofa hex flange at the base of the solenoid.

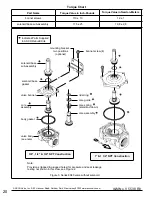

Installation of Panel Mounted Solenoid

(See Figures 1 and 2)

Install solenoid base sub-assembly through customer panel.

8202H panel mounted solenoids include a retainer to adapt the

solenoid base sub-assembly to the customer panel. (See Figure 2)

Position finger washer on opposite side of panel over solenoid

base sub-assembly.

Replace solenoid, nameplate/retainer and red cap.

Make electrical hookup, see Wiring section.

Disassemble solenoid following instruction under

Solenoid

Replacement

then proceed.

2.

3.

4.

1.

5.

Solenoid Temperature

Standard solenoids are designed for continuous duty service. When

the solenoid is energized for a long period, the solenoid becomes

hot and can be touched by hand only for an instant. This is a safe

operating temperature.

MAINTENANCE

A WARNING: To prevent the possibility of death,

serious injury or property damage, turnoff electrical

power, depressurize solenoid operator and/or valve,

and vent fluid to a safe area before servicing.

Cleaning

All solenoid operators and valves should be cleaned

periodically. The time between cleaning will vary depend-

ing on medium and service conditions. In general, if the

voltage to the solenoid is correct, sluggish valve operation,

excessive noise or leakage will indicate that cleaning is

required. Clean strainer or filter when cleaning the valve.

Preventive Maintenance

•

Keep the medium flowing through the solenoid opera

-

tor or valve. as free from dirt and foreign· material as

possible.

• Periodic exercise of the valve should be considered if

ambient or fluid conditions are such that corrosion, elas

-

tomer degradation, fluid contamination build up, or other

conditions that could impede solenoid valve shifting are

possible. The actual frequency of exercise necessary will

depend on specific operating conditions. A successful op

-

erating history is the best indication of a proper interval

between exercise cycles.

• Depending on the medium and service conditions,

periodic inspection of internal valve parts for damage or

excessive wear is recommended. Thoroughly clean all

parts. Replace any worn or damaged parts.

Causes of Improper Operation

• Faulty Control Circuit:

Check the electrical system by

energizing the solenoid. A metallic click signifies that

the solenoid is operating. Absence of the click indicates

loss of power supply. Check for loose or blown fuses,

open-circuited or grounded solenoid, broken leadwires or

splice connections.

• Burned-Out Solenoid:

Check for open-circuited so-

lenoid. Replace if necessary. Check supply voltage; it

must be the same as specified on nameplate/retainer and

marked on the solenoid. Check ambient temperature and

check that the core is not jammed.

• Low Voltage:

Check voltage across the solenoid leads.

Voltage must be at least 85% of rated voltage.

Solenoid Replacement

1. Disconnect conduit, coil leads, and grounding wire.

NOTE:

Any optional parts attached to the old solenoid must

be reinstalled on the new solenoid. For 3-way construction,

piping or tubing must be removed from pipe adapter.

2. Disassemble solenoids with optional features as follows:

• Spade or Screw Terminals

Remove terminal connections, grounding screw, ground-

ing wire, and terminal block (screw terminal type only).

NOTE:

For screw terminals, the socket head screw holding

the terminal block serves as a grounding screw

.

• Junction Box

Remove conduit and socket head screw (use 5/32” hex key

wrench) from center of junction box. Disconnect junction

box from solenoid.

• DIN Plug Connector

Remove center screw from DIN plug connector. Disconnect

DIN plug connector from adapter. Remove socket head

screw (use 5/32” hex key wrench), DIN terminal adapter,

and gasket from solenoid.

1

2