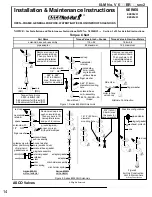

Upstream for

pressure testing

(upper tap & plug)

Partial side view of valve body

showing location of tapped and

plugged holes for pressure and

seat leakage testing

OUT

FLOW

IN

Downstream for

seat leakage testing

(lower tap & plug)

Downstream tap & plug on

bottom of valve body for

3/4” NPT construction

1/8” pipe plug

(3/16 hex key wrench)

Figure 2. Provisions for pressure and seat leakage testing.

Testing for Internal (Seat)Leakage

CAUTION: Be sure valve can be tested without

affecting other equipment.

1.

Using a 3/16 hex key wrench, remove the 1/8” pipe plug

from the downstream side of the valve body. Then install

suitable test piping (e.g.; two short nipples and an elbow

or tubing) to check for leakage.

2.

Block fl ow downstream of valve.

3.

Restore electrical power supply and pressurize valve to

nameplate rating.

4.

With valve de

-

energized, immerse end of test piping in

a cup of water for 20

-

30 seconds and look for bubbles,

which would be indicative of seat leakage. Repeat this

procedure at several progressively lower pressures, down

to approximately 1/4 psi. Between each test, remove cup

of water and operate valve.

5.

If seat leakage is detected, turn off electrical power and

depressurize valve. Disassemble and check for proper

placement of parts, or any foreign matter that may have

entered the valve. Clean as necessary, reassemble and re

-

test valve for both external and internal leakage.

6. If no seat leakage is detected, remove test piping. Apply a

small amount of Loctite Corporation’s PST Pipe Sealant

567 (or equivalent) to the pipe plug threads. Reinstall the

pipe plug and tighten securely.

7.

Test for external leakage as described in

Piping

section.

8.

When maintenance is complete, operate the valve a few

times to be sure of proper operation. A metallic click

indicates the solenoid is operating.

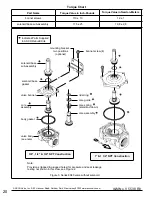

ORDERING INFORMATION FOR

ASCO REBUILD KITS

Parts marked with an asterisk(*) in the exploded view are

supplied in Rebuild Kits. When Ordering Rebuild Kits for

ASCO Valves, order the Rebuild Kit number stamped on the

valve nameplate. If the number of the kit is not visible, order

by indicating the number of kits required, and the Catalog

Number and Serial Number of the valve(s) for which they are

intended.

I&M No. V 5538 R8

©ASCO Valve, Inc.®

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

1

9