ASCO Valves®

All Rights Reserved.

I&M No. V 5538 R8

©ASCO Valve, Inc.®

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

E226722 - 5/12

I&M No. V 5538 R8

Installation & Maintenance Instructions

2-WAY DIRECT-ACTING SOLENOID VALVES

NORMALLY CLOSED OPERATION — 3/8” , 1/2” , 3/4” , 1” OR 1 1/4” NPT

AIR OR FUEL GAS SERVICE

Positioning

This valve is designed to perform properly when mounted in

any position. However, for optimum life and performance, the

solenoid should be mounted vertically and upright to reduce

the possibility of foreign matter accumulating in the solenoid

base sub

-

assembly area.

Mounting

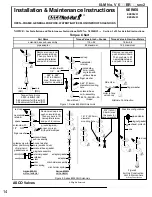

For mounting bracket (optional feature) dimensions, refer to

Figure 1.

SERIES

8040

8041

[42]

1.66

Ø

.28 dia.

2 mounting holes

Figure 1. Mounting bracket dimensions

NOTICE: See separate solenoid installation and

maintenance instructions for information on: Wiring,

Solenoid Temperature, Causes of Improper Operation,

Coil or Solenoid Replacement.

DESCRIPTION

Series 8040 valves are 2-way normally closed direct-acting

solenoid valves designed for air or fuel gas service. Valve

bodies are made of rugged aluminum with trim and internal

parts made of steel and stainless steel. Series 8040 valves are

provided with a general purpose solenoid enclosure.

Series 8041 and EF8040 valves are the same as Series

8040 except they are provided with an explosionproof or

explosionproof/watertight solenoid enclosure.

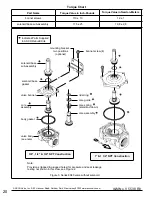

Provisions for Pressure and Seat Leakage Testing

(See Figure 2)

Series 8040G valves are provided with two 1/8” tapped and

plugged holes. One upstream for pressure testing; one down

stream for seat leakage testing. Leakage testing frequency

shall be at least annually in accordance with NFPA

-

86 or

original equipment manufacturer recommendations. Testing

is also required after valve disassembly and reassembly for

inspection, cleaning or rebuilding.

OPERATION

Normally Closed:

Valve is closed when solenoid is de

-

energized; open when energized.

NOTE: No minimum operating pressure differential required.

INSTALLATION

Check nameplate for correct catalog number, pressure, voltage,

frequency, and service. Never apply incompatible fl uids or

exceed pressure rating of the valve. Installation and valve

maintenance to be performed by qualifi ed personnel.

Temperature Limitations

For valve ambient and fl uid temperatures, refer to chart below.

Piping

Connect piping to valve according to markings on valve body.

Apply pipe compound sparingly to male pipe threads only. If

applied to valve threads, the compound may enter the valve

and cause operational diffi culty. Avoid pipe strain by properly

supporting and aligning piping. When tightening the pipe, do

not use valve or solenoid as a lever. Locate wrenches applied

to valve body or piping as close as possible to connection

point. Valves should be checked for external leakage at piping

connections after installation,

see Testing for External Leakage

section.

CAUTION: To avoid damage to the valve body, DO

NOT OVERTIGHTEN PIPE CONNECTIONS. If PTFE

tape, paste, spray or similar lubricant is used, use

extra care when tightening due to reduced friction.

CAUTION: To protect the solenoid valve, install a

strainer or fi lter suitable for the service involved in

the inlet side as close to the valve as possible. Clean

periodically depending on service conditions. See

ASCO Series 8600 and 8601 for strainers.

[ 7.1]

Catalog

Number

Catalog

Number

Prefi x

Min. and Max.

Ambient

Temperatures

Min. and Max.

Fluid

Temperatures

8040G21

8040G22

8040G23

None, KF,

SF, SC or EF

-40

°

F (-40

°

C)

to 125

°

F (52

°

C)

-40

°

F (-40

°

C)

to 125

°

F (52

°

C)

HT, KH, ST,

SU or EFHT

-40

°

F (-40

°

C)

to 140

°

F (60

°

C)

-40

°

F (-40

°

C)

to 140

°

F (60

°

C)

8040A021

8040A022

8040A023

U, MU

32

°

F (0

°

C) to

125

°

F (52

°

C)

32

°

F (0

°

C)

to 125

°

F (52

°

C)

1

7