I&M No.V6584R11

E

ASCO Valve, Inc.

R

50 Hanover Road, Florham Park, New Jersey 07932 www.ascovalve.com

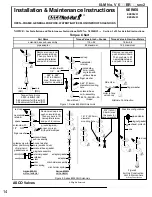

Torque Chart

Part Name

Torque Value in Inch--Pounds

Torque Value in Newton--Meters

terminal block screws

10 ± 2

1,1 ± 0,2

socket head screw

15 --- 20

1,7 --- 2,3

center screw

5 ± 1

0,6 ± 0,1

screw terminal

adapter

gasket

DIN terminal

adapter

socket head screw

socket head

grounding screw

Open---Frame Solenoid

Open---Frame Solenoid

Open---Frame Solenoid

with Screw Terminals.

Socket head screw is

used for grounding.

with DIN Terminals.

tapped hole for

#10---32 grounding screw

(not included)

See

torque chart

above

terminal

block

screw

with 1/4

I

Spade Terminals

(5/32

I

hex key wrench)

(5/32

I

hex key wrench)

Indicates parts supplied

in Termination Module

Kit No. K256104

z

z

z

z

z

z

z

Figure 4. Open---frame solenoids

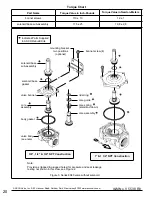

cover screw

cover gasket

cover

junction box gasket

junction box with

and grounding terminal

socket head screw

screw terminal block

(see note)

grounding screw

and cup washer

Junction Box Solenoid

Note:

Junction box with screw terminals

shown. With screw terminal

block removed, remaining parts

comprise the junction box for

spade terminal construction.

See

torque chart

above

or Screw Terminals

(5/32

I

hex key wrench)

1/2

I

conduit connection

with 1/4

I

Spade Terminals

Figure 5. Junction box (optional feature)

gland nut

gland gasket

washer

socket head screw

gasket

DIN terminal

connector

connector cover

center screw

adapter

gasket

(see note 1)

DIN connector

terminal block

(see note 2)

Indicates that these parts are included

Open---Frame Solenoid

in DIN plug connector Kit No. K236034

See

torque chart

above

with DIN Terminal

Plug Connector

Notes:

1. Connector cover may be

position shown for alternate

position of cable entry.

2. Refer to markings on DIN

connector for proper

electrical connections.

rotated in 90

_

increments from

(5/32

I

hex key wrench)

Figure 6. DIN plug connector kit No. K236034 (optional feature)

1

5

I&M No. V 6584 R16_sec2