Description

Name

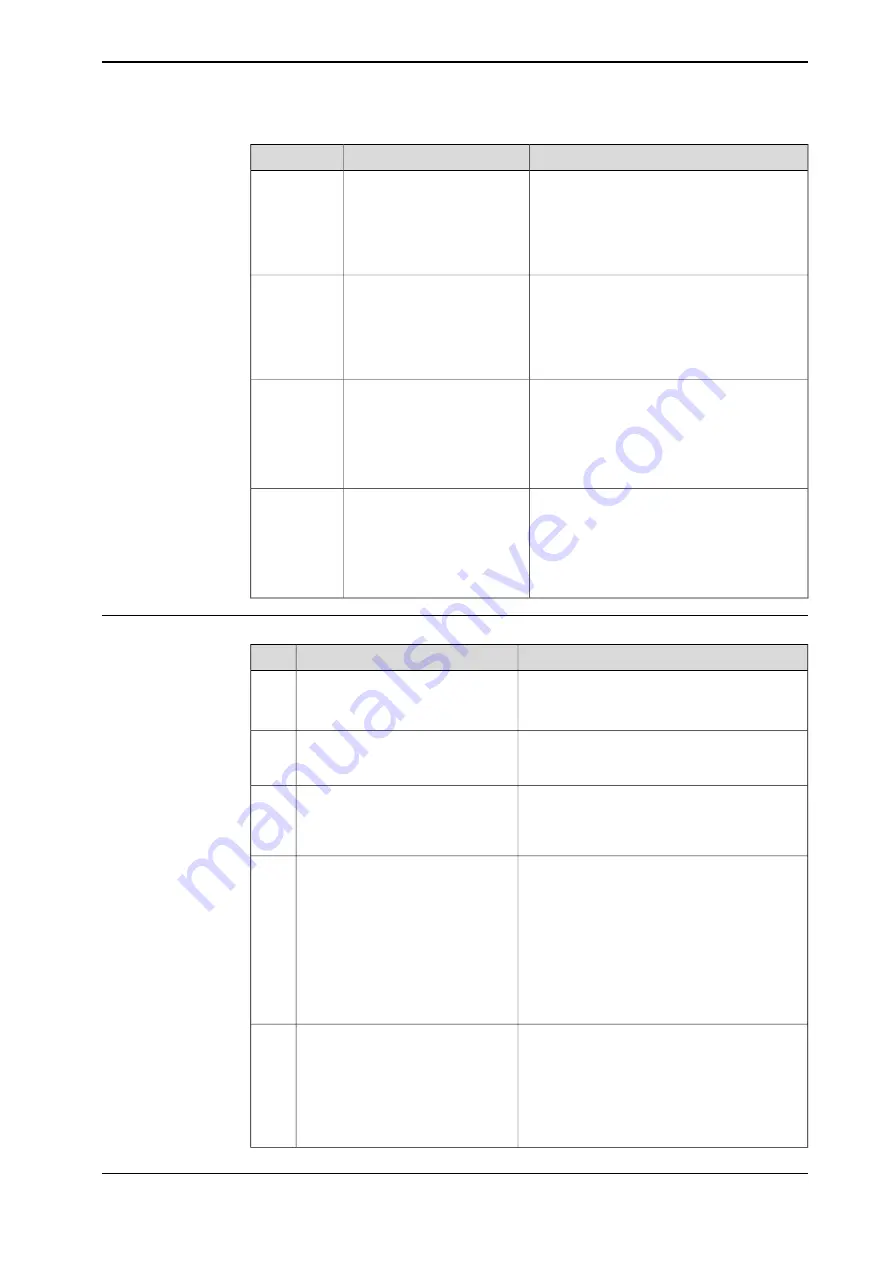

Automatic Stop LED can be used to identify

the following status:

•

No color (not lit): Automatic Stop input

loop is open.

•

Green, solid: Automatic Stop input

loop is closed.

Automatic Stop LEDs (green)

AS1:Automatic Stop LED

channel 1

AS2:Automatic Stop LED

channel 2

AS1 & AS2

General Stop LED can be used to identify the

following status:

•

No color (not lit): General Stop input

loop is open.

•

Green, solid: General Stop input loop

is closed.

General Stop LEDs (green)

GS1:General Stop LED

channel 1

GS2:General Stop LED

channel 2

GS1 & GS2

Emergency stop output LED can be used to

identify the following status:

•

No color (not lit): Emergency stop

output is in State 0 (0V) status.

•

Green, solid: Emergency stop output

is in State 1 (24V) status.

Emergency stop output LEDs

(green)

ESO1:Emergency stop out-

put LED channel 1

ESO2:Emergency stop out-

put LED channel 2

ESO1 & ESO2

External emergency stop LED can be used

to identify the following status:

•

No color (not lit): External emergency

stop input loop is open.

•

Green, solid: External emergency stop

input loop is closed.

External emergency stop

LEDs (green)

ES1:External emergency

stop LED channel 1

ES2:External emergency

stop LED channel 2

ES1 & ES2

Troubleshooting procedure

Note

Action

Wait at least 1 min after power-on.

Make sure the power has been off

for more than 10 seconds.

1

Power on the controller.

•

If LED TRK is green, proceed with

.

•

If LED TRK is not green, proceed with

.

Check LED TRK on Power distribu-

tion board, DSQC1085.

2

•

LED PC and LED HMI are green, pro-

ceed with

.

•

LED PC and LED HMI are not green,

proceed with

.

Check LEDs PC (Power distribution

board, DSQC1085) and HMI (Safety

board, DSQC1087).

3

If the STAT LED is:

•

Green, steady: Application is ready and

unit is operational. Proceed with step

•

Green (uneven flashing ~1Hz): Installa-

tion Utility Application loaded and ready

for recovery operation. Proceed with

step

•

Off or red flashing: The unit is faulty and

needs to be replaced. Proceed with step

Check the STAT LED on the pro-

cessor board (DQSC1086).

4

If the PWR LED is:

•

Green, steady: Unit is operational. Pro-

ceed with step

•

Green (pulsing ~1Hz): Communication

error to PS-side application. Proceed

with step

.

•

Off or red: Proceed with step

.

Check LED PWR on Processor

board, DSQC1086.

5

Continues on next page

Product manual - OmniCore V400XT

417

3HAC081697-001 Revision: A

© Copyright 2022-2023 ABB. All rights reserved.

7 Troubleshooting

7.3.11 Troubleshooting the main computer

Continued

Содержание OmniCore V400XT

Страница 1: ...ROBOTICS Product manual OmniCore V400XT...

Страница 2: ...Trace back information Workspace 23D version a22 Checked in 2024 01 15 Skribenta version 5 5 019...

Страница 180: ...This page is intentionally left blank...

Страница 338: ...This page is intentionally left blank...

Страница 342: ...This page is intentionally left blank...

Страница 428: ...This page is intentionally left blank...

Страница 460: ...This page is intentionally left blank...

Страница 464: ......

Страница 465: ......