L2234

L2778

Emax

15/158

Doc. No.

Model

Apparatus

Scale

Page No.

1SDH000460R0002

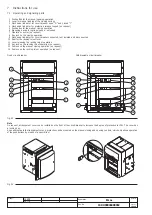

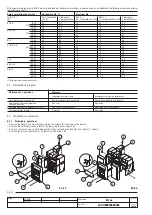

6.

Putting into service

6.1 General procedures

– Check tightness of the power connections at the circuit-breaker terminals

– Carry out all the preparatory operations on the release

– Make sure that the value of the auxiliary circuit power supply voltage is between 85 and 110% of the rated voltage of the electrical applications

– Make sure that there is an adequate air circulation in the place of installation to avoid overheating

– Also carry out the checks specified in the following table.

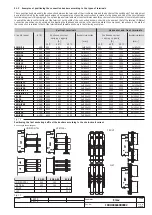

Item inspected

1 Manual operating mechanism

2 Geared motor (if any)

3 Undervoltage release

(if any)

4 Shunt opening release (if any)

5 Shunt closing release (if any)

6 Circuit-breaker lock in the open position

(with key or padlocks)

7 Auxiliary contacts of the circuit-breaker

8 Auxiliary contacts for signalling circuit-

breaker connected, test isolated and

disconnected

9 Lock devices for circuit-breakers

connected and disconnected. Interlocking

devices between circuit-breakers side by

side and one on top of another (if any)

10 For withdrawable circuit-breakers: racking

-in/out device

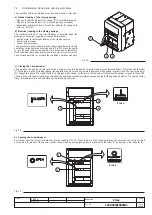

Procedure

Carry out some opening and closing operations

(see the chapter 7.2).

CAUTION

When there is an undervoltage release, the

circuit-breaker can only be closed after the

release has been electrically energized.

Supply the spring loading geared motor at the

corresponding rated voltage.

Carry out some closing and opening

operations.

Note. Supply the undervoltage release at the

corresponding rated voltage (if any).

Supply the undervoltage release at the

corresponding rated voltage and carry out the

circuit-breaker closing operation.

Disconnect voltage to the release.

Supply the undervoltage release at the

corresponding rated voltage and carry out the

circuit-breaker closing operation.

Close the circuit-breaker.

Supply the shunt opening release at the

corresponding rated voltage.

Open the circuit-breaker.

Supply the shunt closing release at its rated

voltage.

Open the circuit-breaker, turn the key and

remove it from its seat. Attempt circuit-breaker

closing operation.

Insert the auxiliary contacts in suitable signalling

circuits. Carry out some circuit-breaker closing

and opening operations.

Insert the auxiliary contacts in suitable signalling

circuits. Then put the circuit-breaker in the

connected, test isolated and disconnected

position.

Carry out the operating tests.

Carry out some racking-in and out operations.

Positive check

The spring loading lever moves correctly.

The springs are loaded correctly.

The signals are correct.

The geared motor stops with the springs

loaded.

The geared motor reloads the springs after

each closing operation.

The circuit-breaker closes correctly. The signals

are correct.

The circuit-breaker opens. The signal changes

over.

The circuit-breaker opens correctly. The

signals are correct.

The circuit-breaker closes correctly. The signals

are correct.

Both manual and electrical closing are

prevented.

The signals are given correctly.

The signals due to the relative operations are

given correctly.

The locks function correctly.

Racking-in operation: the circuit-breaker racks

in correctly. The first turns of the crank handle

do not meet with particular resistance.