3

2. Forced ventilation

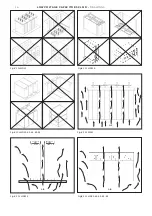

Forced cooling using a fan is sometimes required (Fig.

#6). Please refer to the following recommendations:

• Consider the maximum ambient temperature of the

installation site including the heating effect of the

capacitor installation itself.

• Consider the heat dissipated from all the compo-

nents and apparatus in the cubicle: reactors, capaci-

tors, contactors, fuses, etc.

• Consider the maximum permissible temperatures for

all the components and apparatus.

• Consider how to direct the airflow with respect to

the position of the capacitors (Fig. #6).

3. The use of an overtemperature protection is recom-

mended in order to switch the bank off in case of fan

failure or overtemperature due to other cause.

4. Regular maintenance and cleaning of any filters is

necessary. Without regular cleaning the cooling system

may become inefficient.

CLMD13 group assembly

To make a group of several CLMD13 capacitor units (up

to 4 maximum):

1. CLMD13 units are delivered with top protection cov-

ers already mounted. Unscrew them before assem-

bling.

2. Place the CLMD13 capacitor units on a plane and firm

punched surface (or support bars), side by side. Please

note the CLMD13 orientation is highlighted by top “U”

marking next to its power terminals as well as an arrow

print on the top cover. U and arrow markings must

match. Make sure all CLMD13 of a group have the same

orientation(Fig. #7).

3. Align them together by their black terminal plates

(Fig. #8).

4. Install interconnection bars (optional) between re-

spective terminals and fix them with the delivered

bolts with a torque of 3Nm (recommended torque for

M6 according to DIN 46-200) (Fig. #9).

5. For proper IP protection degree, open the necessary

knock-outs in the top covers for interconnection bars

and put them back over the capacitor units.

CLMD fixation (Fig. #10)

Fix each CLMD unit through its fixation slots with ap-

propriate screws/bolts (not included).

For CLMD33 /33S, at least 4 fixation holes must be

used. Make sure that the rigidity of the support and the

screws are sufficient to bear the weight of the CLMD

capacitor unit(s).

Electrical connection

Power supply

Cables should be rated at minimum 1.5 times the nomi-

nal capacitor current.

Appropriate cable shoes (cable lugs for CLMD33 /33S

type) must be used in accordance with good common

practice of electrical installation.

While tightening the bolt, a torque of

3Nm

Ò

M6

6Nm

Ò

M8

10Nm

Ò

M10

15Nm

Ò

M12

(recommended torque according to DIN46-200)

should be applied for proper electrical connection,

without damaging the cable (not applicable for

CLMD33 / 33S type). Ensure that all connections are

tight and cables pass through the dedicated knock out

and appropriate grommet.

WARNING!

the power cables must be connected at the

side of the terminals without discharge resistor (as

shown (Fig. #11); connections at the side with dis-

charge resistor might damage the cable due to resis-

tors surface temperature.

Earthing

CLMD43-45, 53-63-65, 83-85 fit a M8 terminal under

the protection cover for earthing connection. Use ap-

propriate cable shoes and apply a 6Nm torque for tight

connection. For other CLMD types, earthing is

achieved through fixation points of the enclosure.

Harmonics

Installation of capacitors on networks disturbed by

harmonics may require special precautions especially

when there is a risk of resonance phenomena.

Commissioning

With the equipment isolated from the supply, check:

• Cabling is properly connected ;

• Ambient ventilation is adequate;

• Correct tightness of the connections.

Accessories

(Optional and for CLMD13 only)

Interconnection bars

The interconnection bars allow making one group of

CLMD13 capacitor units connected in parallel. One kit

of three bars is needed for a group of two CLMD13 ca-

pacitor units.

For installation revert to CLMD13 group assembly para-

graph.

Maintenance

1. Ensure safety procedures are completed (see para-

graph “Safety”);

2. Yearly maintenance should include:

• Removal of dust deposits, cleaning of all parts;

• Check of tightness of all electrical connections;

• Check of ambient temperature;

• Check condition of discharge resistors.

While every care is taken to ensure that the information con-

tained in this publication is correct, no legal responsibility

can be accepted for any inaccuracy. We do not accept respon-

sibility for any misuse of the product. The company reserves

the right to alter or modify the information contained herein

at any time in the light of technical or other developments.

en